In most warehouses and manufacturing units, pallet wrapping is one of those jobs that looks simple from the outside but anyone who works on the shop floor knows how much time, labor, and energy it actually consumes. Manual wrapping is slow, tiring, inconsistent, and often leads to loose pallets, wasted stretch film, or unstable loads during transport.

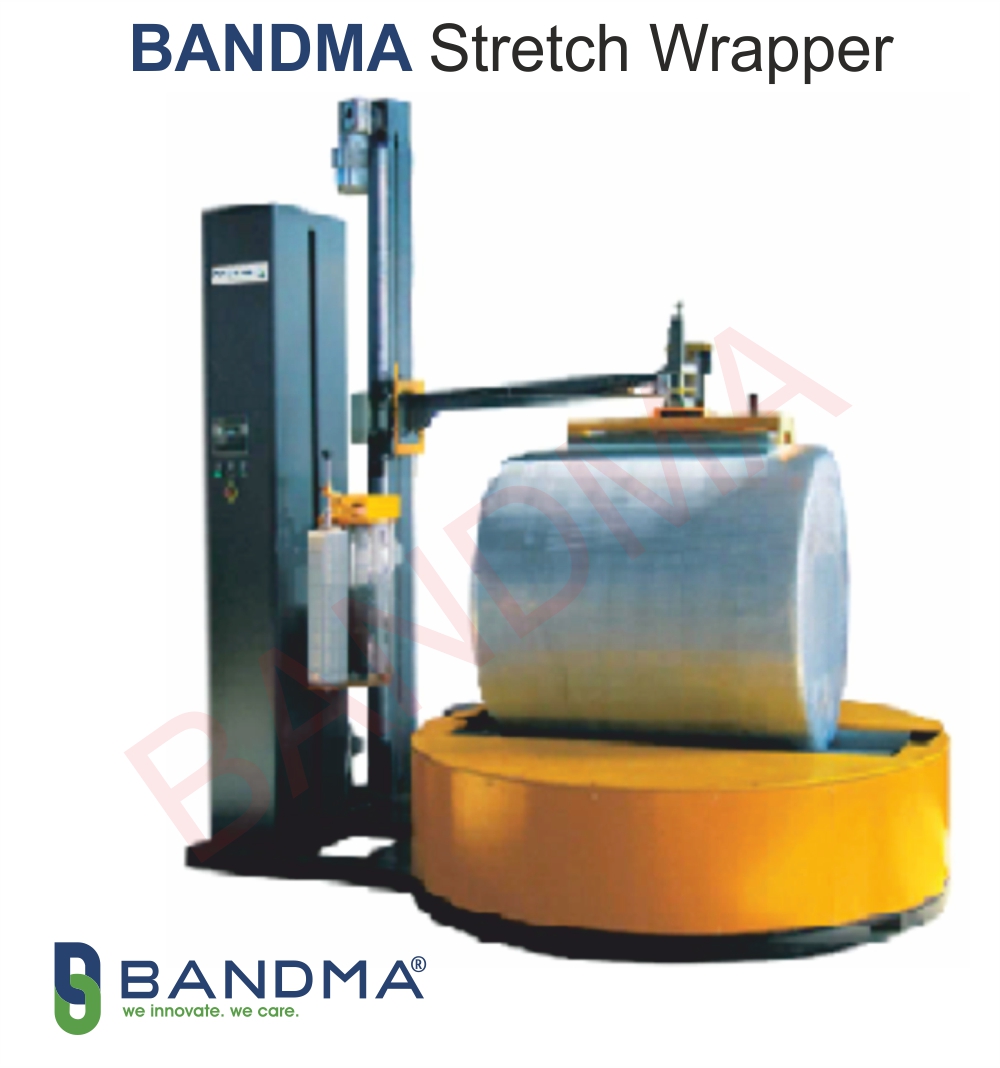

This is exactly where an Automatic Stretch Wrapping Machine changes the game. Instead of relying on manpower and guesswork, the machine delivers tight, uniform, and secure wrapping every time. It not only speeds up the work but also improves the safety of your pallets and reduces packaging costs in the long run.

Let’s break down why automatic stretch wrapping has become the smarter choice for modern warehouses and why so many industries are shifting to automated pallet wrapping systems.

1. Consistent Wrapping, Every Single Time

When pallets are wrapped manually, the tension of the film depends on how fast the worker moves, how tightly they pull, or how tired they are. Naturally, consistency becomes impossible to maintain.

An automatic stretch wrapping machine fixes this by applying even tension, controlled film stretch, and the same number of layers on every pallet. This ensures that:

- The load stays stable

- Products don’t shift during transport

- The pallet doesn’t loosen or lean

- Wrapping quality stays exactly the same throughout the day

Consistency directly reduces product damage, return rates, and customer complaints.

2. Saves Time on Every Pallet

Manual wrapping takes anywhere between 3 to 6 minutes per pallet, depending on the load and the worker. With an automatic stretch wrapper, this time drops significantly because the machine handles the full cycle holding, wrapping, tensioning, and cutting.

On busy shop floors, even a 30–50 seconds saving per pallet becomes a major productivity boost by the end of the shift. This creates an overall smoother workflow, especially during peak dispatch hours.

3. Reduces Film Usage and Cost Wastage

A big advantage of automatic wrapping is controlled pre-stretch technology. The machine stretches the film to a precise percentage before applying it to the pallet. This means:

- You use less film

- The wrap is tighter

- There is almost no wastage

- The cost per pallet reduces

For warehouses handling high pallet volumes every day, this saving becomes noticeable within the first few months of installation.

4. Safe for Workers and Better for Workplace Ergonomics

Anyone who has wrapped pallets manually knows how physically exhausting it is. Workers have to bend, pull, stretch, and walk in circles with a heavy roll of film. This leads to:

- Back pain

- Wrist strain

- Repetitive stress injuries

- Fatigue and slow performance

Automatic machines remove all of these risks. Operators only place the pallet on the turntable or conveyor, press a button, and the machine takes over. This improves both safety and efficiency while reducing workplace injuries.

5. Perfect for High-Volume Warehouses

Companies handling large shipments or daily dispatches can’t rely on slow, manual wrapping. An automatic stretch wrapper keeps up with the pace of modern warehouses by providing:

- Continuous wrapping

- Fast cycle times

- High repeatability

- Reduced downtime

Whether you’re packing 30 pallets or 300 pallets a day, the machine handles the load smoothly without tiring out or slowing down.

6. Better Load Stability During Transport

Transport damages are one of the biggest hidden costs for manufacturers. Poor wrapping leads to:

- Shifting loads

- Leaning pallets

- Torn film

- Product breakage

- Rework and replacements

Automatic stretch wrapping ensures a tight hold from top to bottom, keeping the pallet secure throughout the transport journey whether it’s by road, rail, or air.

7. Simple Operation and Low Maintenance

Modern stretch wrapping machines are designed to be easy for operators. With simple controls, preset modes, and quick adjustments, even new workers can use them without difficulty. Maintenance is minimal because the machine uses strong components and stable mechanics that hold up well in industrial environments.

Most units can run for long hours with only basic service checks, making them a reliable addition to your packaging area.

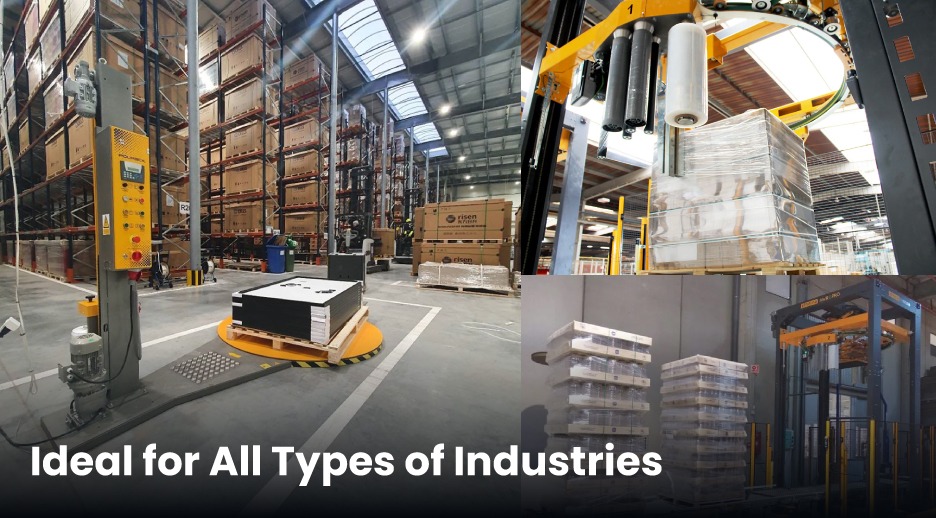

8. Ideal for All Types of Industries

One of the biggest strengths of automatic stretch wrapping machines is their flexibility. They work smoothly with different pallet sizes, product types, and load weights. Industries that commonly use them include:

- FMCG

- Food and beverage

- Logistics and warehousing

- Pharmaceuticals

- Retail distribution

- Electronics

- Automotive parts

- Chemical and paint industries

No matter what the product is, stable pallet wrapping is always a key part of safe movement and storage.

Conclusion:

A Smarter, Faster, and Safer Way to Wrap Pallets

As manufacturing and warehousing demands grow, manual pallet wrapping is no longer practical or efficient. An automatic stretch wrapping machine delivers the speed, consistency, safety, and cost savings that modern operations need. It doesn’t just wrap pallets it improves the overall flow of your dispatch system, reduces labor dependency, and ensures better product protection.

For businesses looking to upgrade their packaging section, an automatic stretch wrapper is one of the most practical and high-impact investments you can make.