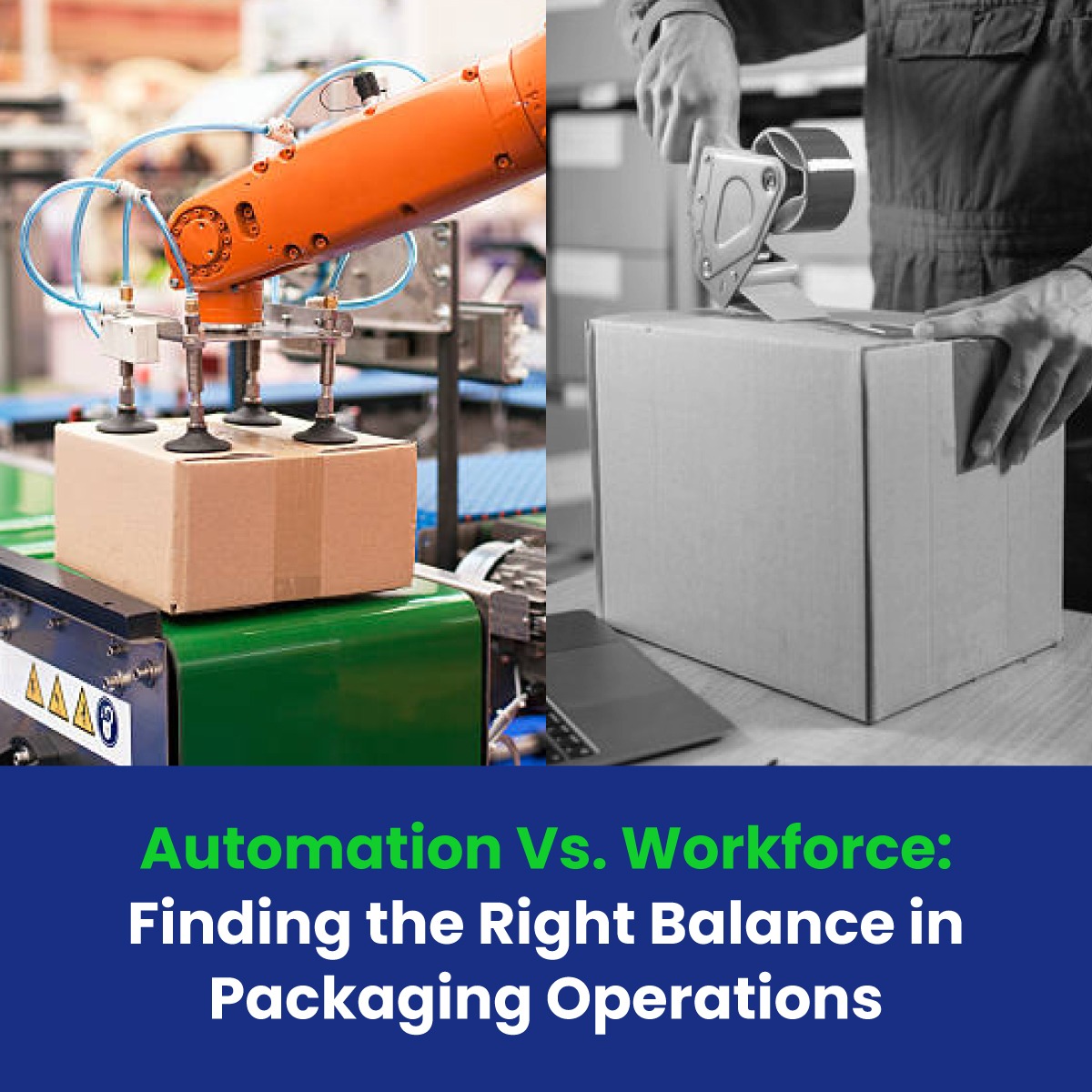

In today’s fast-paced manufacturing and logistics industry, packaging plays a critical role in ensuring products reach customers safely and on time. But when it comes to choosing the right approach—automation or manual labor—businesses often face a tough decision. Should you invest in high-end automated systems or rely on your existing workforce? Or is there a way to combine both for maximum efficiency?

This debate is more relevant than ever in 2025, with rising labor costs, increasing order volumes, and pressure to deliver faster without compromising quality. In this blog, we’ll explore the pros and cons of both approaches and help you understand how to find the perfect balance for your packaging operations.

Why Packaging Efficiency Matters More Than Ever

Packaging isn’t just about wrapping products. It impacts:

- Product safety: Poor packaging can lead to damage during transit, costing businesses in returns and refunds.

- Operational speed: Faster packaging means quicker deliveries, which customers expect today.

- Cost management: Labor, materials, and energy consumption all affect your bottom line.

When the competition is fierce, optimizing your packaging line becomes essential. And this is where the question arises: Should you automate or stick with manual processes?

The Case for Automation in Packaging

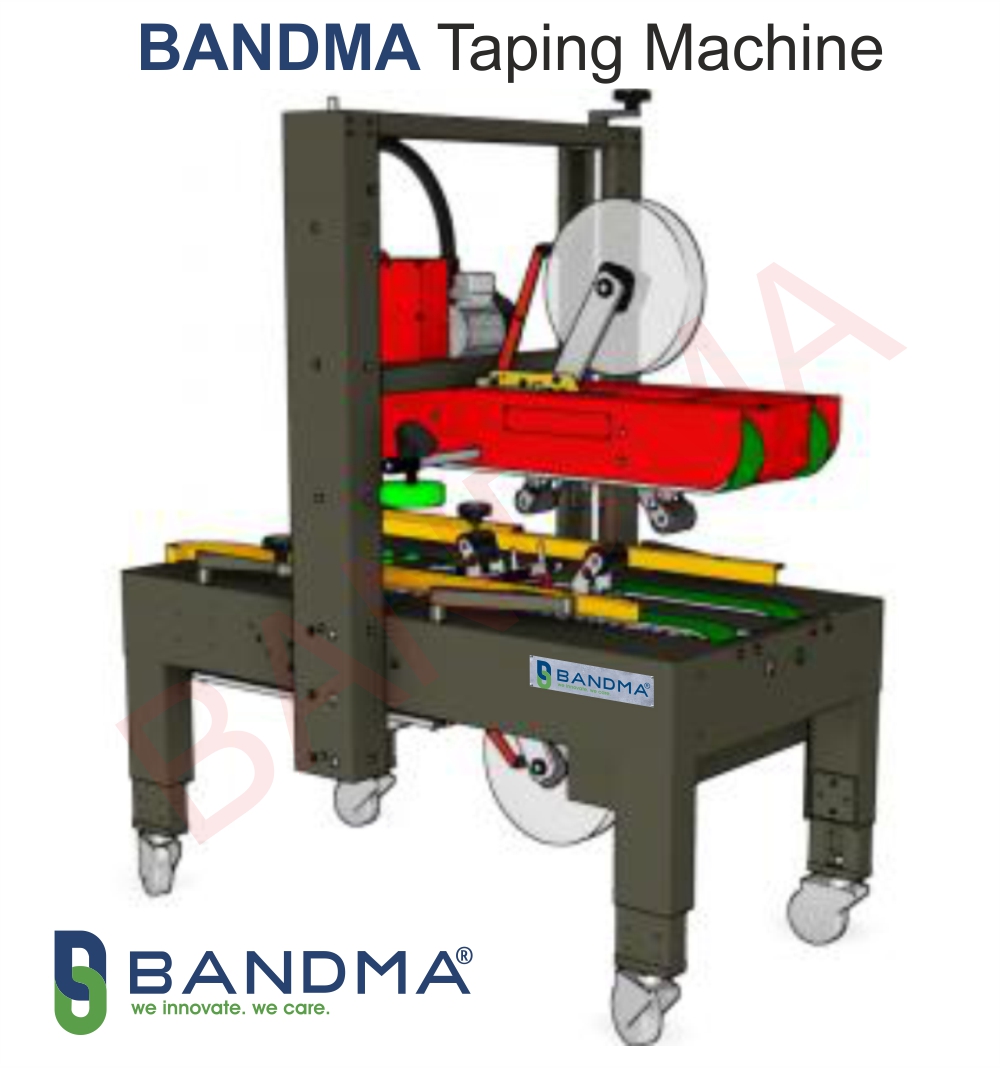

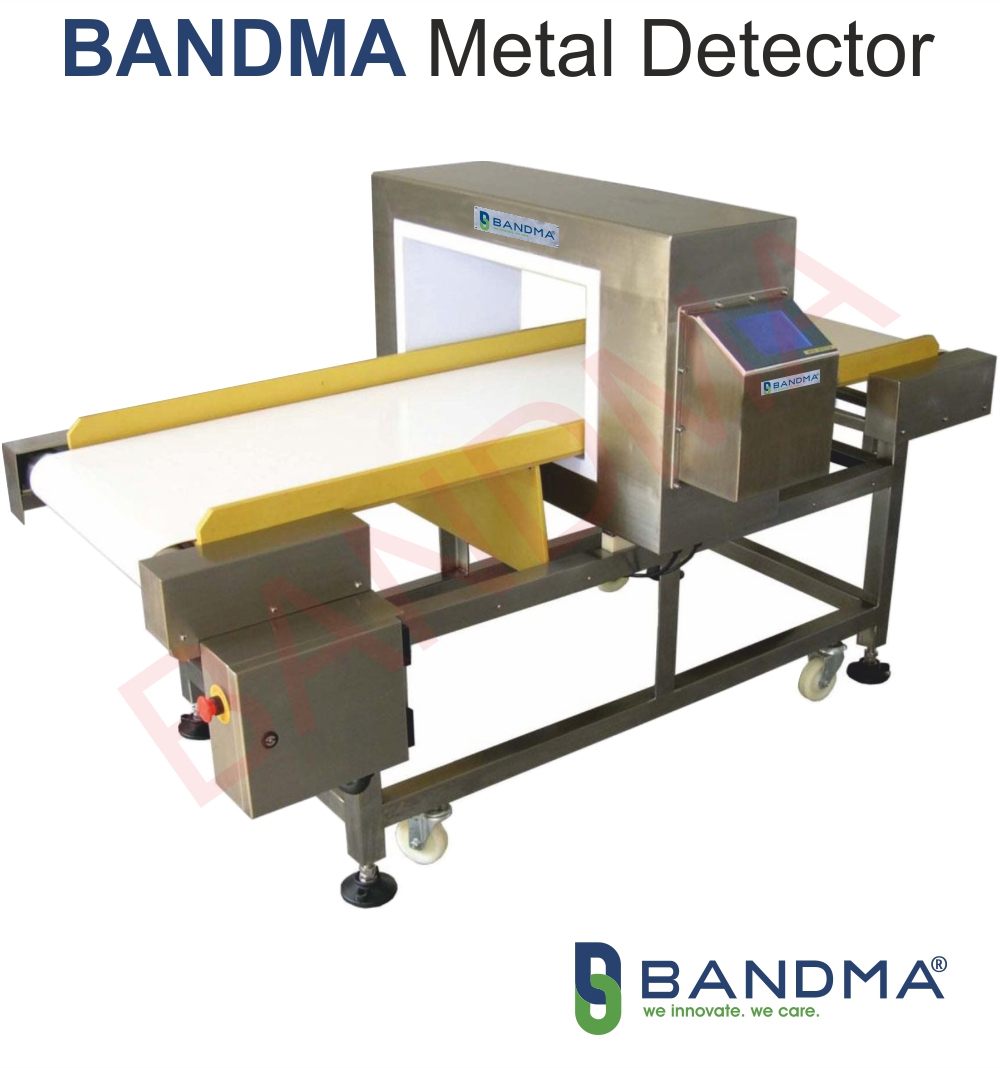

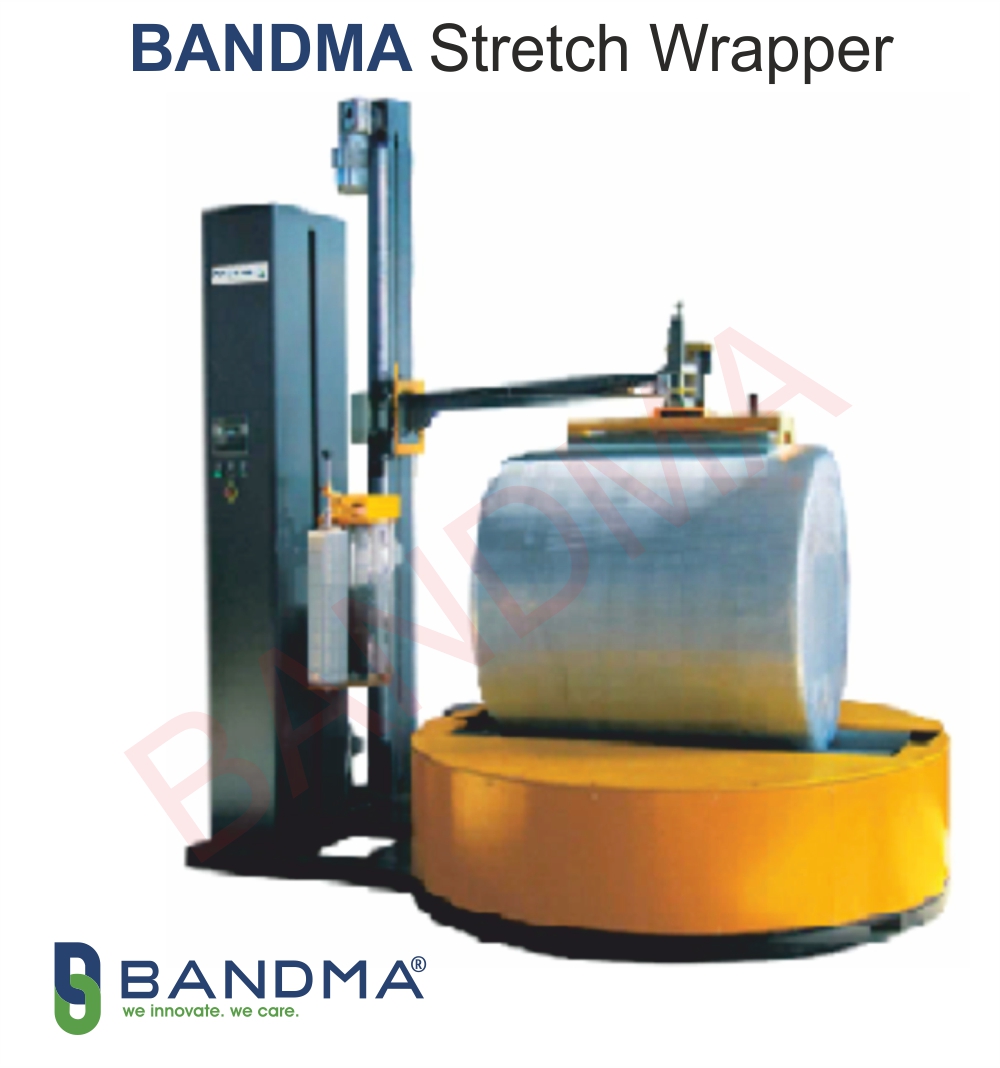

Automation in packaging involves machines like strapping systems, stretch wrappers, case sealers, and robotic palletizers that reduce manual intervention. These solutions are designed to improve speed, accuracy, and consistency.

Advantages of Automation

- Higher Speed and Throughput

Automated machines work faster than humans. A case sealer or strapping machine can process dozens of boxes per minute without fatigue, ensuring you meet high-volume demands. - Consistent Quality

Machines apply the same tension, wrap, or seal every time—reducing errors caused by human fatigue or inexperience. - Lower Long-Term Costs

While the initial investment may seem high, automation reduces labor dependency, overtime costs, and errors that lead to product damage. - Improved Safety

Repetitive tasks like lifting heavy loads or bending to strap boxes can lead to injuries. Automation minimizes these risks by taking over strenuous jobs.

Limitations of Automation

- High Initial Investment: Automated equipment requires significant capital.

- Maintenance and Downtime: Machines need regular servicing, and breakdowns can halt operations.

- Less Flexibility: For small-scale or highly customized packaging, manual handling may still be better.

The Case for Workforce-Driven Packaging

Despite technological advances, human workers bring adaptability and decision-making that machines can’t match. For businesses with smaller operations or seasonal variations, manual labor can still be a cost-effective solution.

Advantages of Manual Packaging

- Lower Upfront Cost

You don’t need to spend lakhs or crores on machinery—just skilled labor and basic tools. - Flexibility for Custom Jobs

If your packaging involves irregular shapes or frequent changes, humans can adjust quickly without programming new settings. - Easy to Scale Down

For businesses with fluctuating demand, hiring temporary workers is easier than buying and maintaining machines.

Challenges with Manual Packaging

- Slower Output: Human speed cannot match automated systems.

- Inconsistency: Errors like loose straps or uneven wrapping can lead to product damage.

- Higher Long-Term Costs: Overtime, training, and workplace injuries can increase expenses over time.

Finding the Right Balance: Automation + Workforce

The real question isn’t “Automation OR Workforce?” but rather “How do you combine both effectively?” The best approach often lies in hybrid packaging operations—using automation for repetitive tasks and relying on human intelligence for complex or irregular jobs.

Steps to Achieve Balance

- Analyze Your Packaging Volume

High-volume operations benefit more from automation. Low to medium volumes can remain manual or semi-automated. - Start Small with Semi-Automation

Machines like semi-automatic strapping systems or stretch wrappers reduce fatigue and improve consistency without replacing your workforce entirely. - Train Your Workforce to Handle Automation

Instead of eliminating jobs, upskill employees to operate, monitor, and maintain machines. This creates a win-win situation. - Focus on ROI, Not Just Cost

Automation is an investment, not an expense. Calculate long-term savings from reduced labor, fewer errors, and faster turnaround times. - Keep Flexibility for Custom Orders

Automation works best for repetitive tasks. For unique or special packaging, your workforce can handle the creative part.

Future of Packaging Operations: What 2025 and Beyond Hold

The trend is clear—smart factories and Industry 4.0 are transforming packaging. AI-driven machines, IoT sensors for predictive maintenance, and collaborative robots (cobots) are becoming common. However, humans remain vital for quality checks, supervision, and adapting to unexpected challenges.

The future isn’t about machines replacing people; it’s about machines supporting people to work smarter, not harder.

Conclusion

Balancing automation and workforce is no longer an option—it’s a necessity for sustainable growth. The right mix depends on your business size, budget, and future goals. By investing in semi-automation first, training your workforce, and gradually upgrading, you can achieve efficiency without losing the human touch that defines your brand.

Remember, automation brings speed and consistency, but your workforce brings adaptability and creativity. Together, they make your packaging line unstoppable.