In the fast-paced world of packaging, efficiency and product integrity are critical to business success. The packaging industry, especially when it comes to bottles, demands solutions that not only protect the contents but also maintain their presentation and appeal. That’s where advanced bottle wrapping machines by Bandma come into play, setting a new benchmark in packaging technology.

Bandma's bottle wrapping machines are transforming how companies store and display their bottled goods thanks to their creative designs, state-of-the-art technology, and dedication to dependability. This article examines the characteristics, advantages, and effects of various devices to make sure your packing procedure is as reliable as your final product.

The Role of Bottle Wrapping Machines in Modern Packaging

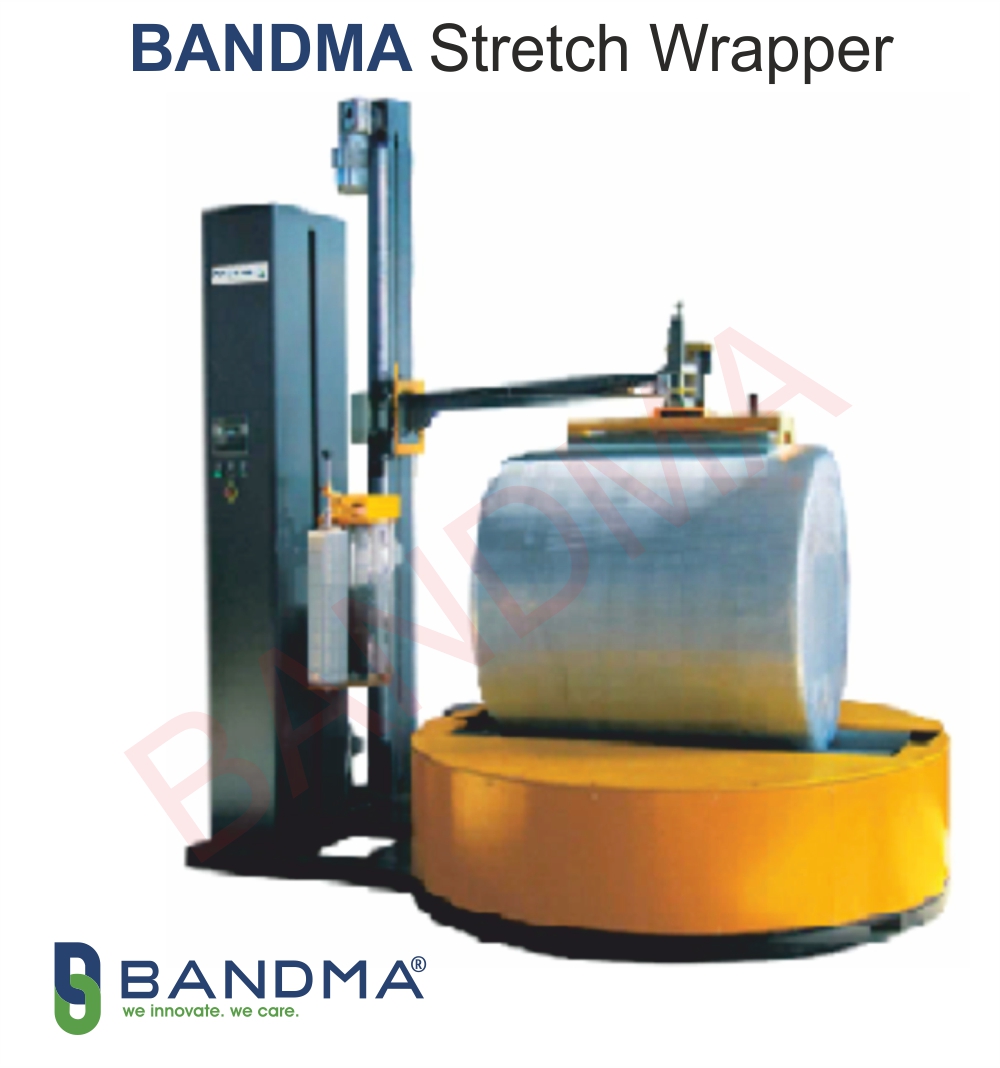

Bottle wrapping machines are made especially to make it easier to wrap bottles, either one at a time or in bundles, using materials like stretch wrap or shrink film. These devices are essential for:

- Protecting products from dust, moisture, and potential damage during transit.

- Preserving product quality by sealing the contents in a controlled environment.

- Enhancing shelf appeal with clear, professional wrapping that showcases the product.

Bandma’s advanced solutions go a step further by integrating precision, efficiency, and user-friendly features into every machine.

Key Features of Bandma’s Bottle Wrapping Machines

1. Versatility in Applications

A variety of bottle shapes, sizes, and materials can be handled by Bandma's bottle wrapping machines. These machines guarantee a flawless wrap every time, whether the bottles are made of metal, plastic, or glass.

2. High-Speed Operations

In the cutthroat market of today, efficiency is crucial. High-speed wrapping capabilities provided by Bandma's machines guarantee higher production rates without sacrificing quality.

3. Advanced Wrapping Technology

Outfitted with the newest wrapping technology, these devices provide safe, impenetrable packing by employing stretch wrapping or heat-sealing techniques.

4. User-Friendly Design

Bandma places a strong emphasis on usability. Their bottle wrapping machines are perfect for companies of all sizes because of their user-friendly controls, automated features, and low maintenance needs.

5. Robust Build Quality

Designed to last, Bandma's machines are made to endure the demands of industrial operation while continuing to operate reliably over time.

Benefits of Using Advanced Bottle Wrapping Machines

1. Enhanced Product Protection

SBottles that are securely wrapped are protected from contamination, spillage, and damage while being transported and stored.

2. Cost Efficiency

Automated wrapping is a cost-effective solution for high-volume packaging operations because it lowers labor expenses and material waste.

3. Improved Aesthetics

A product's visual appeal is improved by clean wrapping, which increases its attractiveness to customers when displayed on store shelves.

4. Increased Productivity

Businesses can manage larger orders and meet deadlines thanks to high-speed machinery that drastically reduce packaging time.

5. Environmental Responsibility

Bandma's wrapping solutions are made to maximize the use of film while cutting waste and encouraging environmentally friendly packaging techniques.

Applications Across Industries

Bandma’s bottle wrapping machines cater to a variety of industries, including:

1. Beverage Industry

In the fiercely competitive beverage sector, properly wrapped bottles guarantee quality and attractiveness for everything from water and soft drinks to alcoholic beverages.

2. Pharmaceutical Industry

Reliable packaging protects bottles of medications and health supplements against contamination and tampering, preserving the integrity of the product.

3. Personal Care Products

To improve shelf presentation and stop leaks, bottles of shampoos, lotions, and other personal care products should be securely wrapped.

4. Food Industry

To satisfy safety regulations and draw in customers, sauces, oils, and other liquid food items need to be packaged in a sanitary and long-lasting manner.

Why Choose Bandma for Bottle Wrapping Solutions?

1. Trusted Expertise

Bandma has a track record of meeting client expectations and industry standards by providing superior packaging solutions.

2. Cutting-Edge Innovation

Bandma incorporates the newest technologies into their equipment with an emphasis on continual improvement, guaranteeing unparalleled performance and dependability.

3. Comprehensive Support

Bandma offers end-to-end support, from installation to after-sales care, guaranteeing a flawless experience for its customers.

4. Customization Options

Bandma is aware that every company has different requirements. Their equipment can be modified to meet particular packaging specifications, offering specialized solutions for the best outcomes.

Future Trends in Bottle Wrapping Technology

1. Smart Automation

Bottle wrapping machines are getting smarter as technology develops, with features like AI-driven automation and Internet of Things connectivity to improve productivity and monitoring.

2. Eco-Friendly Materials

The development of machines that work with recyclable or biodegradable wrapping materials is being driven by the trend toward sustainable packaging.

3. Compact and Portable Designs

Compact devices that provide excellent performance without taking up a lot of room are getting more and more popular as space becomes more valuable.

4. Enhanced Speed and Precision

Upcoming developments will concentrate on improving wrapping accuracy and speed, cutting downtime, and boosting output.

Conclusion

Protect, preserve, and perfect—Bandma's sophisticated bottle wrapping machines fulfill this promise. These devices offer the perfect balance of effectiveness, dependability, and beauty whether you're packing drinks, medications, or personal hygiene items.

Businesses may improve their packaging operations, minimize expenses, and increase the appeal of their products in cutthroat marketplaces by investing in Bandma's innovative solutions.

Choose Bandma’s bottle wrapping machines and experience the future of packaging today!