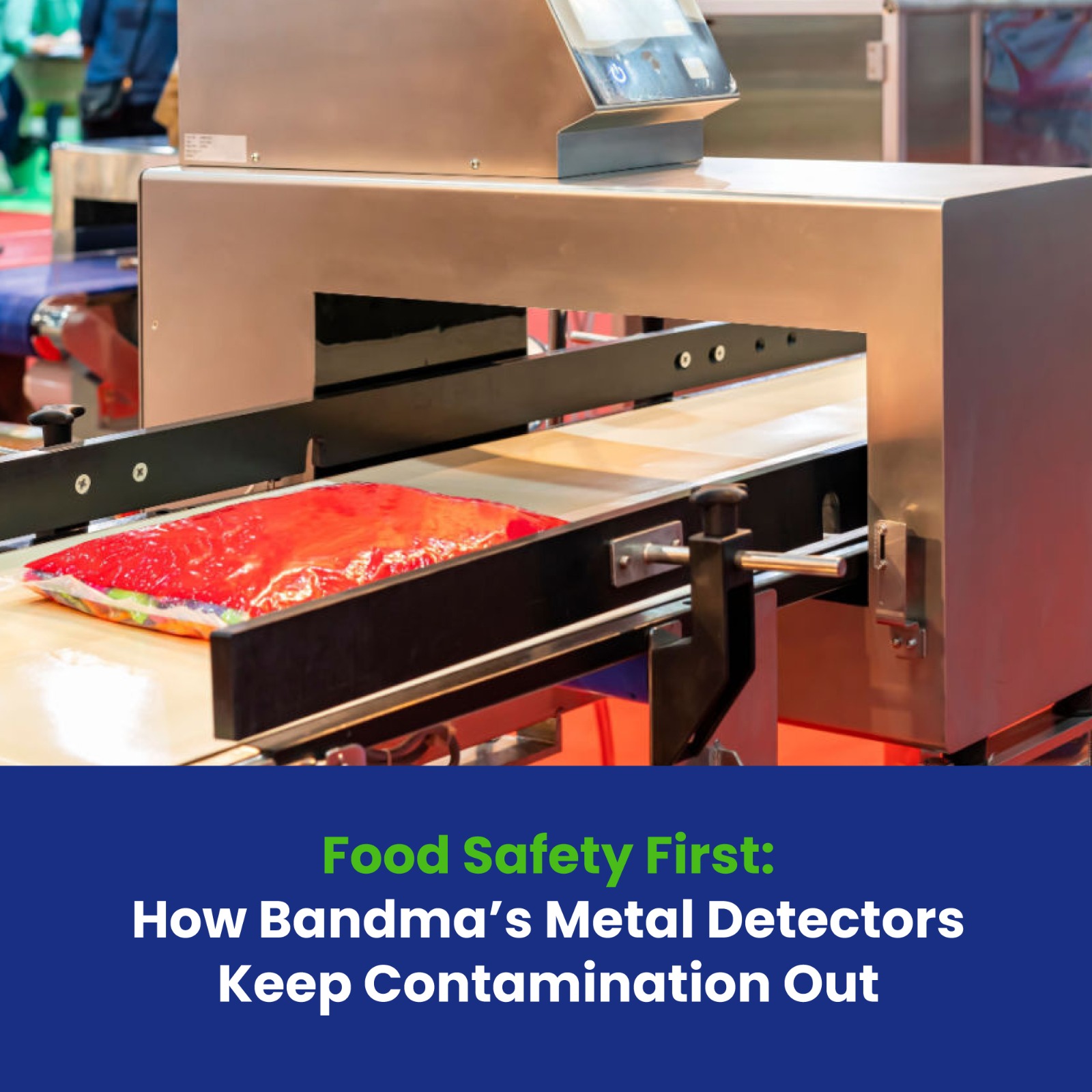

In the food industry, Safety is of utmost importance in the food industry. Customers rely on brands to provide them with tasty items that are also devoid of dangerous impurities. Upholding the strictest food safety regulations is essential in a world where even a minor mistake can result in widespread recalls, harm to one's reputation, and health hazards. In order to identify and stop contamination before items even make it to the shelves, Bandma's Metal Detectors offer a clever and dependable solution.

At Bandma, we know that food safety always comes first. Let's examine how food producers worldwide are reinventing quality assurance with Bandma's Metal Detection technology.

Why Metal Detection is Critical in the Food Industry

Even with strict production procedures, contamination from foreign materials can still happen. Possible causes of metal particles getting into the food supply chain include wear and tear on machinery, contaminants in raw materials, and unintentional handling mistakes.

If not found and eliminated, metal impurities like stainless steel, ferrous, and non-ferrous metals can be extremely harmful to one's health. Particles as small as this can cause:

- Health issues for consumers

- Product recalls

- Legal penalties

- Brand reputation damage

- Financial losses

The brand and the customer are ultimately protected when a strong metal detection system is put in place to guarantee that products fulfill legal criteria like FDA, HACCP, and BRC regulations

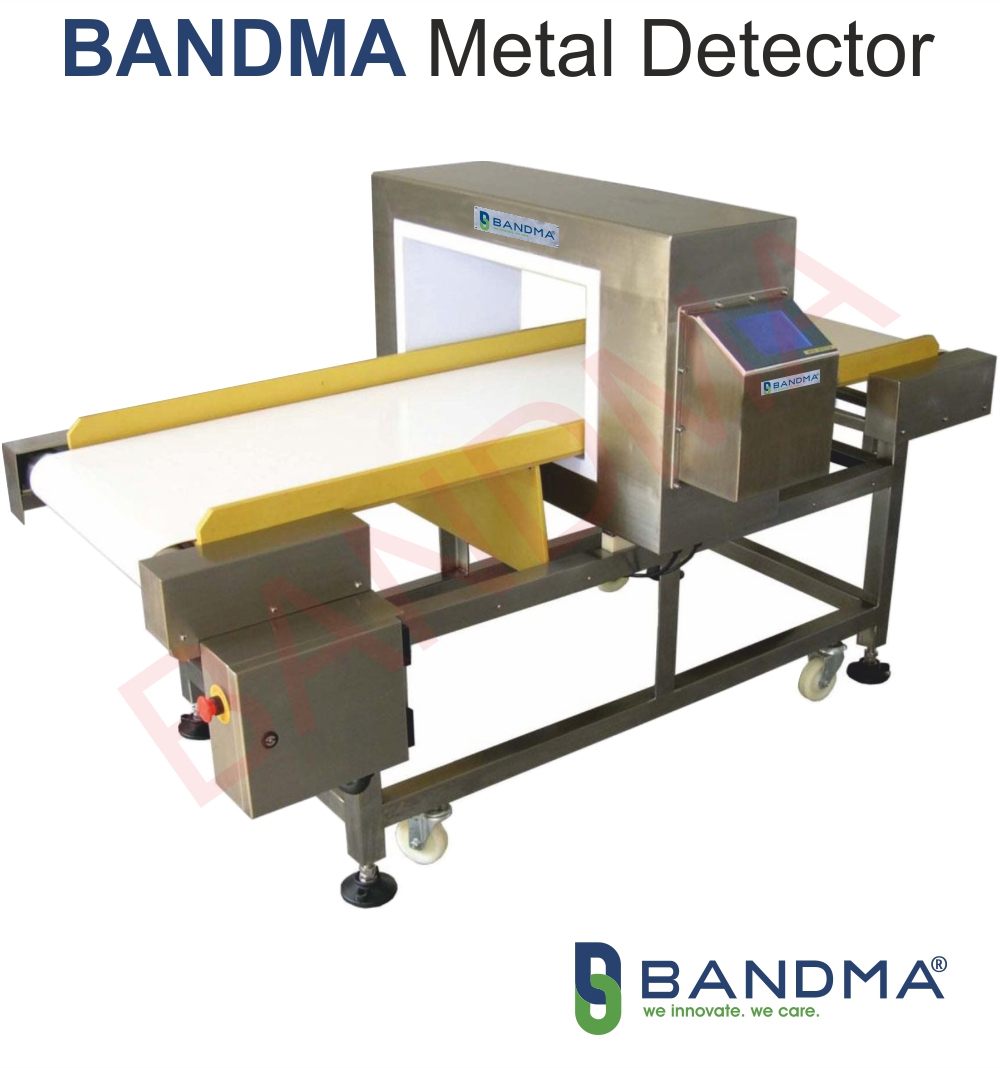

Introducing Bandma’s Metal Detector Solutions for the Food Industry

Bandma offers cutting-edge Metal Detectors that are specifically designed for food processing and packaging environments. Built with advanced technology and precision engineering, our systems ensure that your products are safe, your operations are efficient, and your brand reputation remains untarnished.

Key Features of Bandma Metal Detectors:

- High Sensitivity Detection: Capable of identifying even the smallest metal particles.

- User-Friendly Interface: Easy to operate with minimal training required.

- Customizable Settings: Adjustable to different product types and production lines.

- Durable Design: Built to withstand harsh food processing environments.

- Automatic Rejection Systems: Ensures contaminated products are removed without disrupting production flow.

- Hygienic Construction: Designed for easy cleaning and compliance with food industry hygiene standards.

Whether it’s baked goods, dairy, meat, poultry, seafood, or packaged foods, Bandma’s Metal Detectors ensure a flawless layer of safety in every step of the process.

Benefits of Using Bandma’s Metal Detectors in Food Production

1. Enhanced Consumer Safety

The most important benefit is protecting consumers from accidental ingestion of harmful metal pieces. Bandma’s systems provide reliable detection, ensuring that only safe products make it to market.

2. Regulatory Compliance

Food safety regulations across the world demand rigorous inspection and contamination prevention. Our metal detectors help businesses comply effortlessly with international safety standards.

3. Brand Protection

A single recall can damage a brand’s reputation permanently. By investing in Bandma’s metal detection technology, businesses protect their image and build consumer trust.

4. Cost Efficiency

Catching contamination early prevents the need for expensive recalls, lawsuits, and wasted production runs. Our systems are designed to integrate seamlessly into production lines, maximizing efficiency without compromising safety.

5. Quality Assurance

Consistency is key in food production. Bandma’s metal detectors help ensure that every batch maintains the highest quality, supporting strong customer satisfaction and loyalty.

Applications of Bandma Metal Detectors in the Food Industry

Bandma's Metal Detectors are suitable for a wide range of food industry segments, including:

- Bakery and Confectionery

- Meat and Poultry Processing

- Dairy Products

- Frozen Foods

- Seafood

- Snacks and Ready-to-Eat Foods

- Packaged Goods

Our versatile systems can be installed at various critical control points — including incoming raw material inspection, in-process checks, and final product evaluation — ensuring contamination is caught no matter where it occurs.

Bandma’s Commitment to Innovation and Excellence

At Bandma, innovation is at the heart of everything we do. Our metal detection systems are not just machines; they are a promise — a promise to help food businesses protect their consumers and their brands.

With decades of experience serving industries with high-quality packaging and inspection solutions, Bandma is recognized for:

- Precision Engineering

- Advanced Technology Integration

- Exceptional Customer Support

- Tailored Solutions for Unique Needs

When you partner with Bandma, you’re partnering with a brand that cares deeply about your success — and the safety of every consumer who trusts your product.

Smart Features for the Modern Food Manufacturer

Understanding the fast-paced demands of the food industry, Bandma has integrated several smart features into our metal detectors:

- Auto-Learn Technology:

Quickly calibrates itself to new products, minimizing downtime during changeovers. - Data Logging and Reporting:

Track inspection results digitally for easy reporting and audit readiness. - IP65/69K Protection:

Available models are built to withstand high-pressure washdowns, ideal for strict hygiene environments. - Connectivity:

Optional integration with existing PLC systems for real-time monitoring and control.

This means more efficiency, less manual intervention, and more robust safety for your food production processes.

Success Stories: Bandma in Action

Across food factories, packaging plants, and distribution centers, Bandma’s Metal Detectors have become a crucial part of food safety programs. Our clients have reported:

- Significant reductions in customer complaints

- Faster regulatory audits with seamless documentation

- Higher consumer trust and brand loyalty

- Improved production line efficiency and reduced downtime

With a global network and strong after-sales service, Bandma remains a trusted partner for food businesses committed to excellence.

Conclusion: Choose Safety, Choose Bandma

Food safety is not just a priority — it’s a responsibility. And when it comes to protecting your products and your brand, nothing should be left to chance.

With Bandma’s Metal Detectors, you get more than just a machine — you get peace of mind, operational excellence, and a partner in quality assurance.

Because at Bandma, we believe every product deserves protection — and every consumer deserves trust.

Food Safety First: Trust Bandma to Keep Contamination Out!