In today’s competitive market, the packaging stage is no longer a minor step at the end of production — it’s a crucial part of your business strategy. Packaging protects your product, ensures quality, and communicates your brand’s promise to the customer. And in 2025, with rising customer expectations, increasing labor costs, and tighter industry regulations, the right packaging machine can make all the difference between staying ahead or falling behind.

But here’s the challenge: the market is flooded with packaging machines, each claiming to be the “best.” From simple manual tools to fully automated systems with AI-driven controls, the variety can be overwhelming. Choosing the wrong one can mean wasted investment, poor efficiency, and even damage to your brand reputation.

So, how do you make the right choice? Let’s break it down step-by-step.

1. Understand Your Product Inside and Out

Every great decision starts with clarity. Before you even begin comparing machines, take a close look at the products you need to package:

Every great decision starts with clarity. Before you even begin comparing machines, take a close look at the products you need to package:

- Size and Weight: Are your products small and lightweight, like snacks, or large and heavy, like industrial parts?

- Fragility: Are they sturdy, or do they require extra protection during shipping?

- Shape: Will you be packaging uniform boxes or irregular shapes?

- Material Sensitivity: Do they need protection from moisture, air, or light?

For example:

- A fresh produce supplier may need vacuum sealers to preserve freshness and extend shelf life.

- An electronics manufacturer may require protective shrink wrapping to shield sensitive components from dust and static.

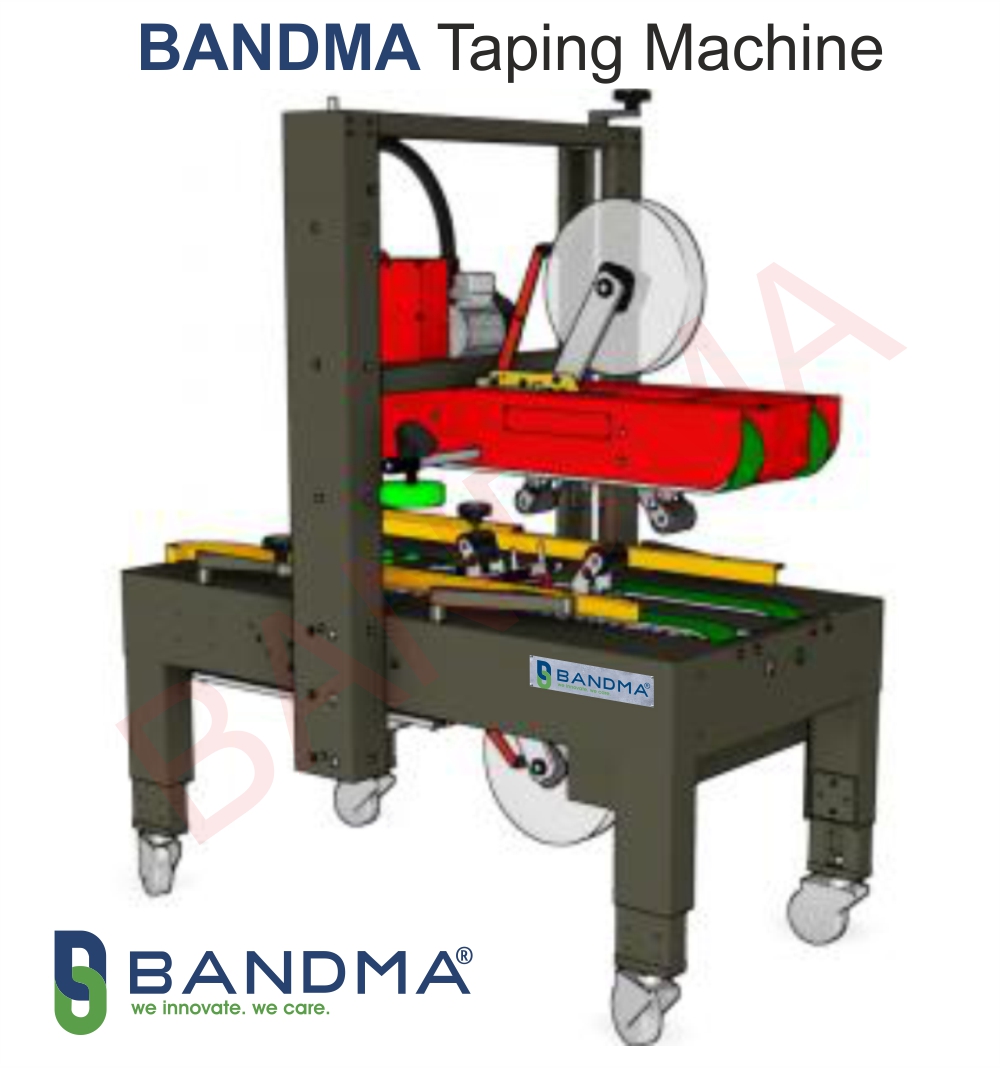

- A logistics company handling heavy shipments could benefit from carton sealers and pallet wrapping machines to secure loads for transport.

When your machine matches your product’s needs, you reduce damage, improve presentation, and save costs in the long run.

2. Decide the Level of Automation You Need

Packaging machines generally fall into three categories:

- Manual Machines – Affordable, but heavily dependent on labor. Suitable for very low production volumes or businesses just starting out.

- Semi-Automatic Machines – A balanced option where some functions are automated, but operators still play a role. Good for medium-scale operations.

- Fully Automatic Machines – High-speed, minimal labor involvement, perfect for large-scale businesses where output and efficiency are top priorities.

Example Scenario:

If your team is packing 300 units a day by hand, you might think semi-automatic equipment will be enough. But if you plan to double production in the next year, jumping straight to a fully automatic system could save time, training, and additional investment later.

3. Compliance and Safety — Non-Negotiables

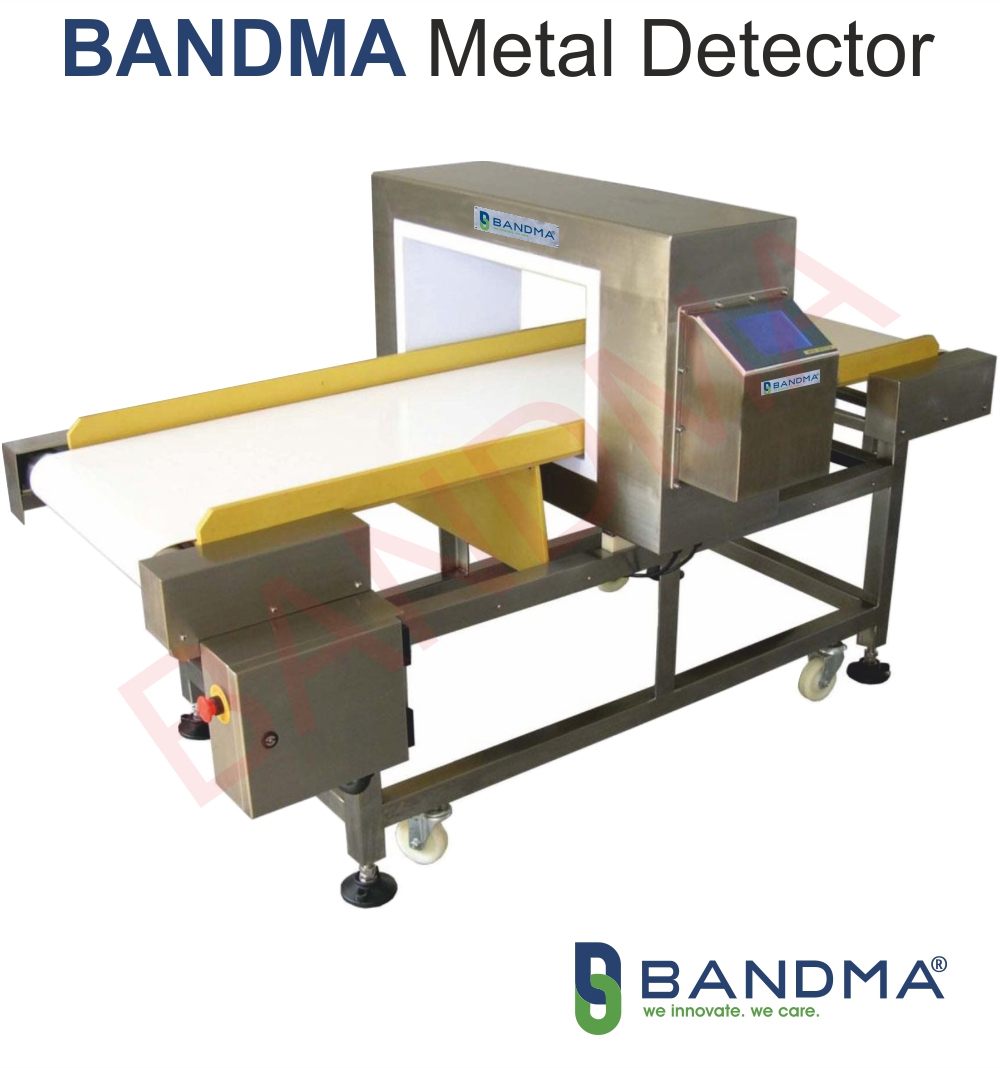

In 2025, regulatory compliance is not just about avoiding fines — it’s about trust. Customers, especially in food, pharmaceuticals, and exports, want proof that products are handled safely and consistently.

Look for machines that meet relevant certifications such as:

- ISO Standards for quality management

- BIS Certification for Indian markets

- CE Marking for European compliance

Certified machines:

- Protect workers from operational hazards

- Ensure your products meet legal export requirements

- Help your brand maintain credibility

If you’re selling overseas, failing to comply can result in rejected shipments — a costly mistake no business can afford.

4. Durability and Service Support — Think Long-Term

A packaging machine is not just another purchase — it’s an asset. You want it to last for years, running reliably day in and day out.

When evaluating options:

- Check the build quality — stainless steel frames often mean better durability and hygiene.

- Ask about recommended operating hours — some machines can run continuously without overheating.

- Inquire about warranty periods and what they cover.

Equally important: after-sales support. Even the best machines will need servicing. Partner with a supplier who offers:

- Readily available spare parts

- Quick technical assistance

- On-site maintenance when needed

Downtime can cost more than the price of the machine itself. Reliable support keeps your production line moving without costly delays.

5. Think in Terms of Total Cost of Ownership (TCO)

A machine’s purchase price is just the beginning. The Total Cost of Ownership includes:

- Maintenance and repairs

- Energy consumption

- Spare parts

- Operator training

- Downtime losses if the machine breaks

Example:

A low-cost carton sealer may seem attractive, but if it breaks down every few months and spare parts take weeks to arrive, you’ll lose more in missed orders than you saved upfront.

6. Plan for Growth and Scalability

Your business will change — that’s the goal. So, choose a machine that can grow with you.

For example:

- A semi-automatic strapping machine that can later be upgraded with a conveyor system

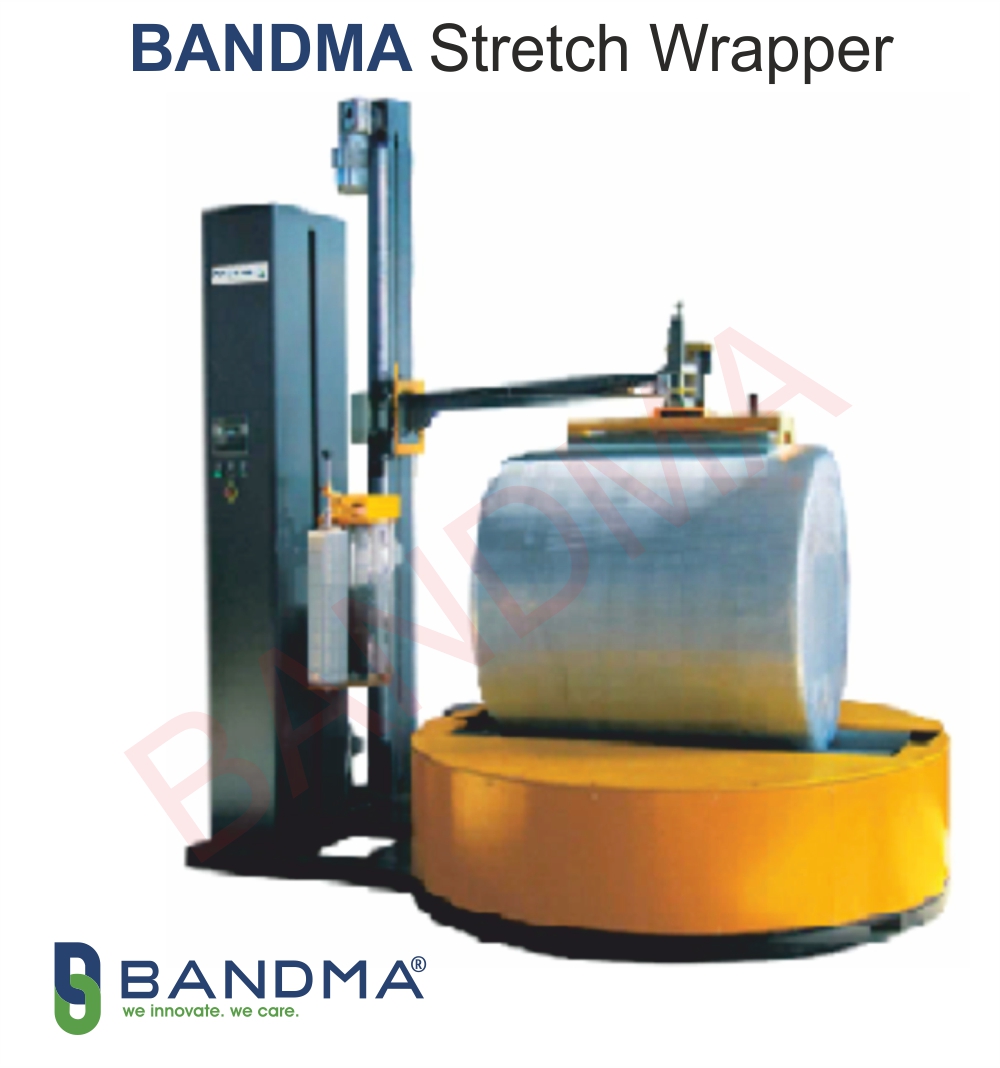

- A stretch wrapper with adjustable settings for different pallet sizes

- A form-fill-seal machine that can handle multiple packaging materials

Buying with scalability in mind prevents you from having to replace machines entirely when your production increases.

7. Always Test Before You Commit

If possible, see the machine in action before you buy. Testing helps you:

- Verify speed and efficiency claims

- Check if the machine handles your exact product well

- Evaluate noise levels, energy use, and ease of operation

If testing in person isn’t possible, ask for video demonstrations with your product samples.

8. Ask the Right Questions

When speaking to a supplier, ask:

- What is the average maintenance cost per year?

- How easy is it to get spare parts locally?

- What kind of training is provided for operators?

- What’s the average machine lifespan under continuous use?

These answers will tell you more than glossy brochures ever could.

Conclusion

Choosing the right packaging machine in 2025 is about balancing present needs with future growth. It’s not just about speed or cost — it’s about finding a machine that aligns with your products, complies with safety standards, minimizes downtime, and scales with your business.

A well-chosen machine becomes a silent partner in your production process — working tirelessly behind the scenes, delivering consistent results, and helping you win customer trust with every package.

In a market where efficiency, quality, and reliability are everything, your choice today will shape your success tomorrow.