In the world of shipping and warehousing, stretch film is one of those everyday items that quietly eats into your budget. Roll after roll, pallet after pallet — the cost adds up faster than most managers realize.

For many businesses, the first instinct when trying to save money on stretch film is to simply buy cheaper rolls or use less wrap. But here’s the problem: cutting corners on wrapping can weaken load security, which can lead to damaged products, returns, customer complaints, and even safety hazards.

The real question isn’t “How can we spend less on stretch film?” but rather “How can we reduce costs while keeping — or even improving — load stability and product protection?”

Let’s break it down into practical, proven strategies.

1. Start with a Load Audit

Before you try to change anything, you need to know what’s really happening on your floor.

Ask yourself:

- How much film is used per pallet?

- Are some operators using more wraps than others?

- Are loads still shifting or toppling during transit?

- Do some products require more protection than others?

A load audit will often reveal waste you didn’t realize was happening. For example:

- A warehouse team might be wrapping light, stable boxes with the same number of layers used for heavy, uneven loads.

- Operators might be applying film too tightly, causing the film to snap — wasting time and material.

By identifying these patterns, you can adjust usage where it matters most.

2. Match the Film to the Job

Not all stretch film is created equal. Using the wrong type is one of the biggest cost drains.

Here are a few common options:

- Blown Film: Excellent puncture resistance, suitable for sharp or irregular loads.

- Cast Film: Smoother, quieter, and offers better cling for uniform loads.

- Pre-Stretched Film: Requires less force to apply, which means less material usage.

Example:

If you’re wrapping light, standard-sized boxes, pre-stretched film can cut usage by up to 50% without sacrificing security. On the other hand, if you’re shipping pallets of jagged metal parts, you’ll need the toughness of blown film to prevent tears mid-transit.

The key is to use the right film for each type of load — not a one-size-fits-all approach.

3. Optimize Your Wrapping Technique

Even the best film will be wasted if it’s applied incorrectly. Common mistakes include:

- Overlapping too much — This wastes film without adding strength.

- Under-stretching — Causes film to sag and lose holding power.

- Over-stretching — Weakens the film and can damage products.

Training your team is essential. Teach operators how to:

- Start with 2–3 wraps at the base to lock the load

- Apply consistent tension without over-pulling

- Work upward in even passes, overlapping just enough for stability

- Finish with a secure top wrap that holds everything in place

Pro Tip: Use a film gauge indicator or pre-set machine tension settings so every pallet is wrapped consistently.

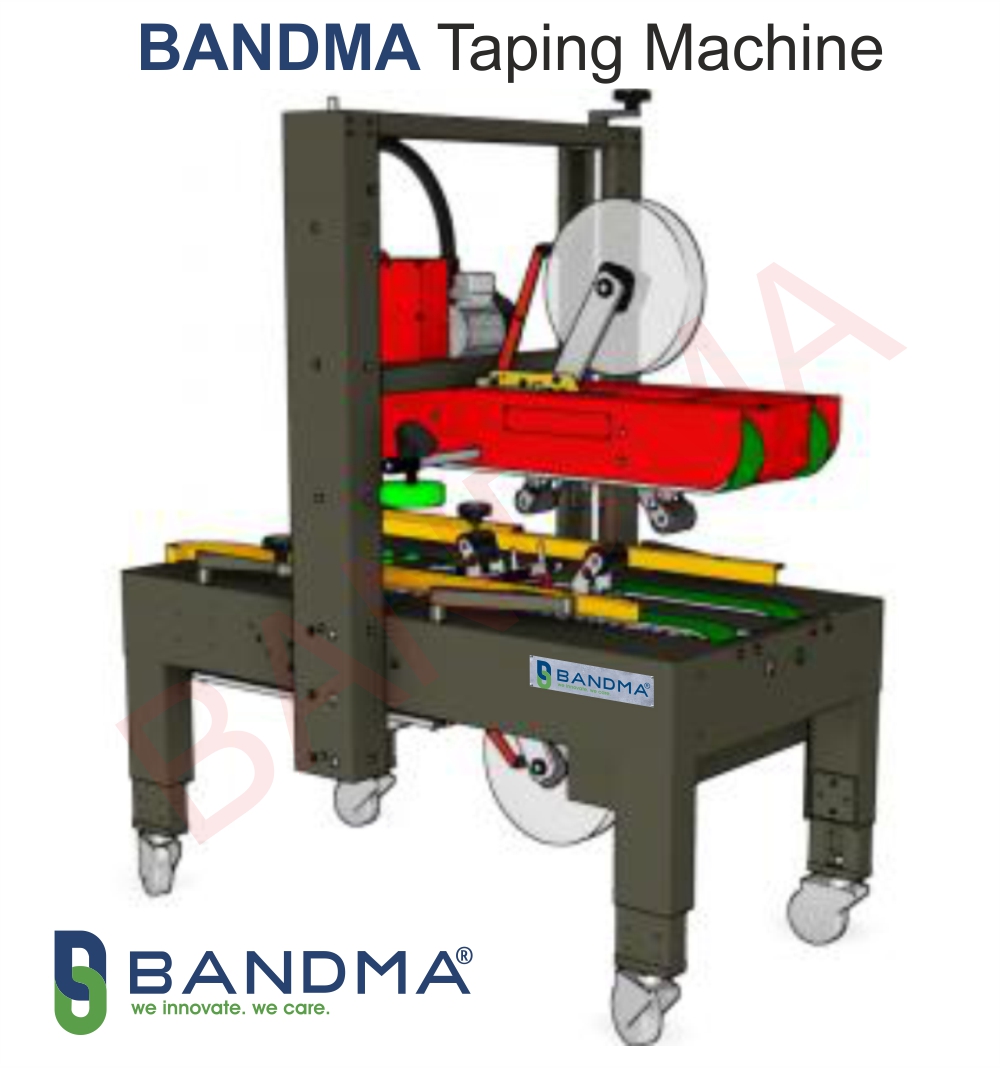

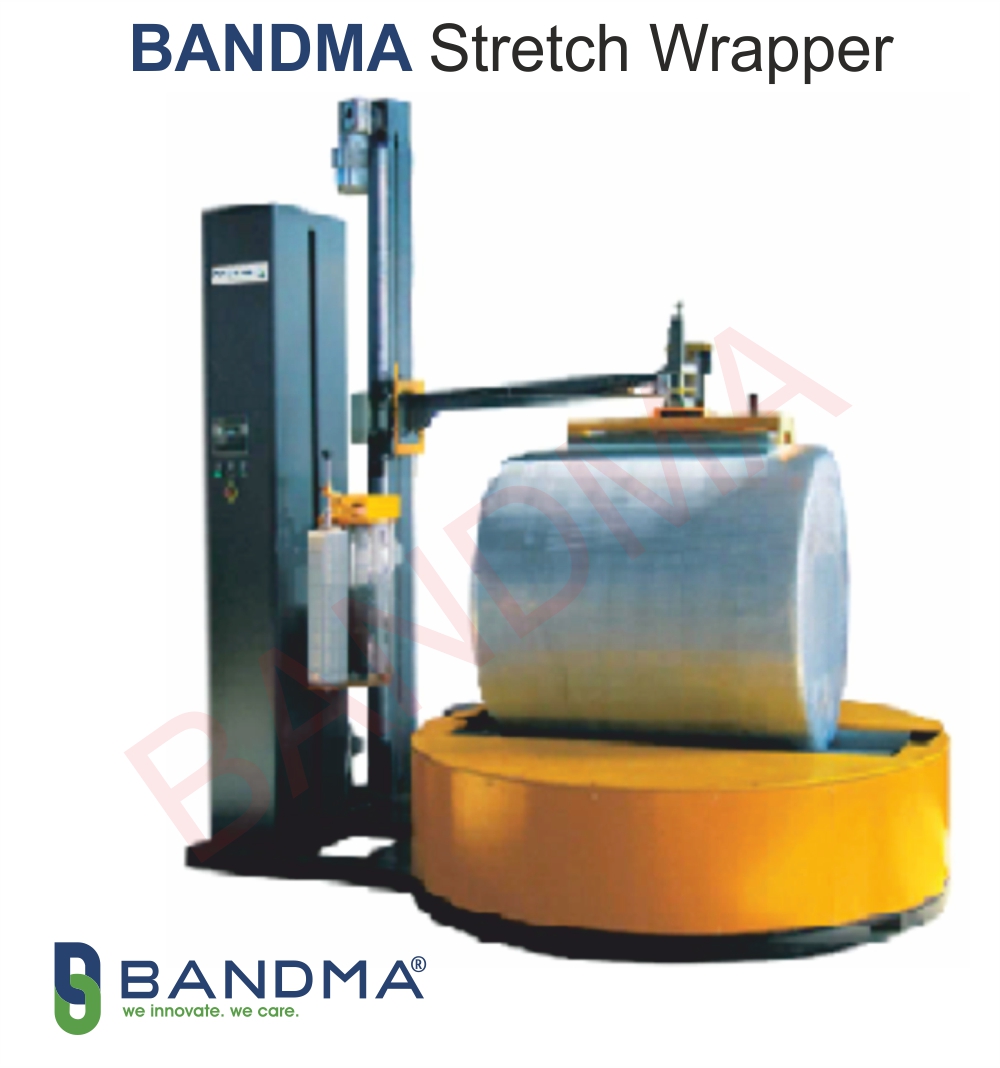

4. Invest in the Right Wrapping Equipment

Manual wrapping is labor-intensive and often inconsistent. Semi-automatic or fully automatic stretch wrappers not only speed up the process but also reduce film usage through precise application.

Benefits of equipment:

- Controlled pre-stretch — machines can stretch film 200–300% before application, using less material for the same holding strength.

- Uniform application — every pallet is wrapped to the same standard.

- Reduced operator fatigue — fewer mistakes from tired workers.

While machines require upfront investment, the long-term savings on labor and film often pay for the equipment within a year or two.

5. Use Film Monitoring Tools

Some advanced stretch wrappers now come with film usage monitoring systems. These tools:

- Track exactly how much film is used per pallet

- Highlight inefficiencies

- Help compare operators or shifts

Even without high-tech tools, you can track usage manually. Keep a simple record of pallets wrapped versus rolls used. Over time, patterns will emerge that help you pinpoint waste.

6. Reduce Waste with Coreless or Thinner Film

Traditional rolls of stretch film come with a heavy cardboard core that ends up in the trash after every use. Switching to coreless rolls not only eliminates waste but also reduces the weight of each roll, making it easier for operators to handle.

Additionally, modern high-performance films are thinner but just as strong as older, thicker varieties. For example, moving from an 80-gauge to a 55-gauge high-strength film could cut material use significantly while maintaining load integrity.

7. Reassess Your Load Configurations

Sometimes the problem isn’t the film — it’s the load itself. Poor stacking or unstable arrangements force you to use more film than necessary.

Check that:

- Boxes are evenly stacked with minimal gaps

- Heavy items are on the bottom

- Pallets are not overloaded beyond their rated capacity

The more stable your load is before wrapping, the less film you’ll need to secure it.

8. Negotiate with Your Supplier

If you’re buying large volumes of stretch film, talk to your supplier about bulk discounts or alternative options. Sometimes suppliers can recommend newer, more cost-effective films that match your needs without sacrificing performance.

9. Combine Savings Strategies for Maximum Impact

The real magic happens when you combine these approaches:

- Audit usage to find waste

- Match the right film to each load type

- Improve operator training

- Invest in efficient wrapping equipment

- Choose high-performance thinner film

This combination can easily cut stretch film usage by 20–40%, which can translate into substantial yearly savings without compromising — and often improving — load security.

Conclusion

Cutting stretch film costs doesn’t have to mean risking damaged goods, rejected deliveries, or unsafe loads. By focusing on the right materials, proper technique, and smart equipment choices, businesses can achieve both savings and stability.

In logistics, small improvements add up. If you can wrap smarter — not just faster or cheaper — your pallets will travel more securely, your customers will be happier, and your bottom line will thank you.