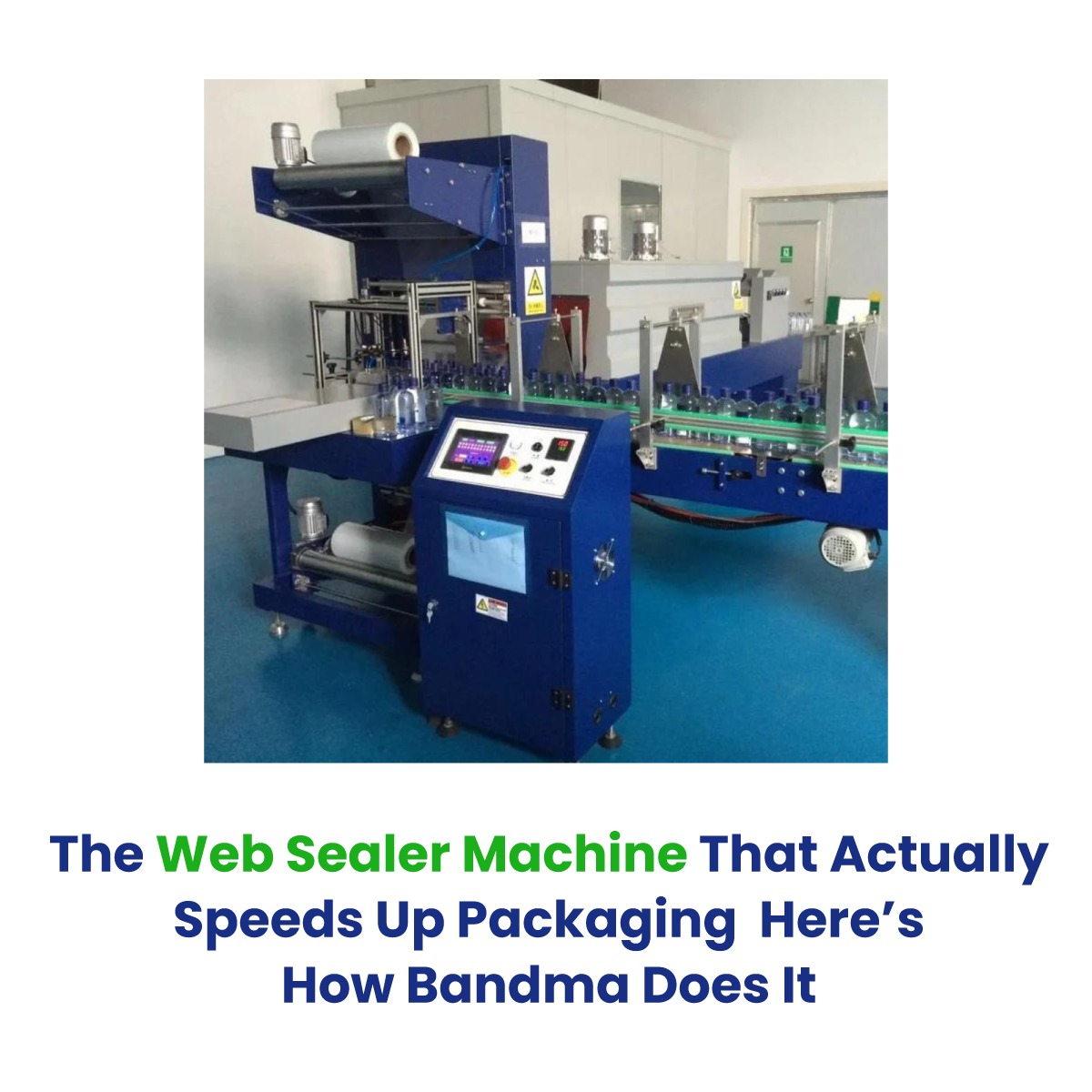

In every manufacturing unit, packaging is the last step yet often the most time-consuming one. Stacking, wrapping, sealing, checking… it all adds up. And when production increases, packaging teams usually feel the pressure first. That’s where a Web Sealer Machine becomes a real game changer.

But let’s be honest: Not every machine that promises “speed” or “efficiency” actually delivers it in real factory conditions. Dust, uneven product sizes, varying load weights, high shift hours these things quickly reveal if a machine is built for real industrial performance or just for the brochure.

Bandma’s Web Sealer Machines stand out because they are engineered around actual shop-floor challenges, not just textbook specifications. Over the years, Bandma has refined its sealing technology based on customer feedback, failures, and thousands of hours of runtime across FMCG, e-commerce, food processing, electronics, and automotive units.

This blog breaks down how Bandma’s Web Sealer Machines genuinely speed up your packaging cycle not just on paper, but in day-to-day operations.

1. Designed to Handle Real-World Packaging Loads

Many web sealer machines struggle with heavy or uneven cartons. Bandma builds its systems with industrial-grade conveyors, solid sealing jaws, and reinforced frames so the machine doesn’t vibrate, shift, or heat unevenly during long-running production.

This stability matters because:

Products don’t tilt or clog while entering the sealing zone

The sealing line stays consistent

Film wrapping remains uniform

Operators don’t need to constantly adjust the settings

The result? Fewer stoppages and a far smoother, continuous packaging flow.

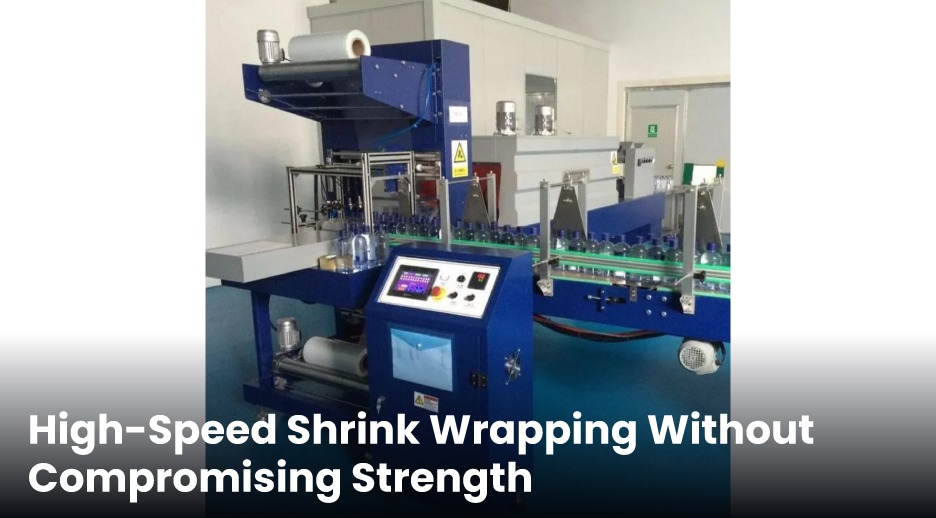

2. High-Speed Shrink Wrapping Without Compromising Strength

Some machines try to run fast and end up damaging the film or creating weak seals. Bandma uses precision-controlled heaters and air-flow systems that shrink the film evenly around small or large products.

This gives you:

- A tight, clean finish

- Protection from dust and moisture

- Better stackability and transport safety

- A professional, retail-ready appearance

Speed only matters when the seal quality stays strong and Bandma machines maintain both.

3. Perfect for Bulk Packaging and Large Product Bundles

A big advantage of Bandma’s Web Sealer is its ability to handle:

- Big cartons

- Multipacks

- Bulk bundles

- Long or tall items

Whether you’re packaging 20 bottles together, a set of cartons, or heavy industrial items, the machine adapts without slipping or misaligning the material. Many industries switch to Bandma specifically because it reduces manual effort in bundling, which is usually the slowest part of the job.

4. Reduces Manual Labor and Human Errors

Before automation, factories needed 3–5 workers to manually wrap, push, and align products. With a Web Sealer, those tasks drop to nearly zero. Operators only need to feed the product, and the machine does the rest:

- Wrap

- Seal

- Shrink

- Convey

Beyond saving manpower, the bigger benefit is consistency. Human wrapping always varies; a machine ensures every product looks identical and perfectly sealed. Consistency is what customers notice and buyers expect.

5. Built for Long Hours and Heavy-Duty Work

Packaging is not an 8-hour job anymore. Many production lines run 12–20 hours per day, especially during peak seasons. Bandma’s Web Sealer Machines are engineered with:

- Overheating protection

- Stabilized temperature controls

- Durable shrink tunnels

- Smooth conveyor systems

- Low-maintenance components

This gives manufacturers the confidence to run the machine continuously without breakdowns—saving both money and time.

6. Faster Changeovers for Different Products

Modern factories deal with multiple SKUs. Bandma machines allow quick adjustments in:

- Conveyor speed

- Film tension

- Sealing temperature

- Tunnel airflow

- Product guides

This reduces downtime whenever you switch from one size or product type to another. In short, more production, less waiting.

7. Low Maintenance and Long-Term ROI

A great packaging machine is not just about performance it’s also about the cost of owning it. Bandma’s Web Sealers are designed to reduce wear and tear so that the machine:

- Needs fewer replacements

- Has lower film wastage

- Consumes optimized power

- Performs consistently over years

Maintenance teams love Bandma machines because they’re simple to service and come with accessible spare parts.

8. Customizable Based on Industry Requirements

Every industry has its own packaging style. Bandma builds Web Sealers that can be tailored for:

- FMCG cartons

- Bottle bundles

- Food trays

- Electronics packaging

- E-commerce parcels

- Industrial kits

Whether the requirement is extra height, wider film, faster conveyor speed, or special tunnel settings—Bandma configures the machine exactly as needed.

Conclusion:

A Web Sealer That Actually Performs Where It Matters

A Web Sealer Machine should do more than heat film and seal cartons. It should enhance your workflow, reduce labor, cut costs, and make packaging faster without compromising quality.

Bandma’s Web Sealer Machines are built with this philosophy. They aren’t just machines—they’re complete packaging solutions designed to keep your production line running smoothly, efficiently, and reliably.

If your factory is looking for a way to increase output without adding extra manpower or complexity, a Bandma Web Sealer may be the most practical upgrade you can make.