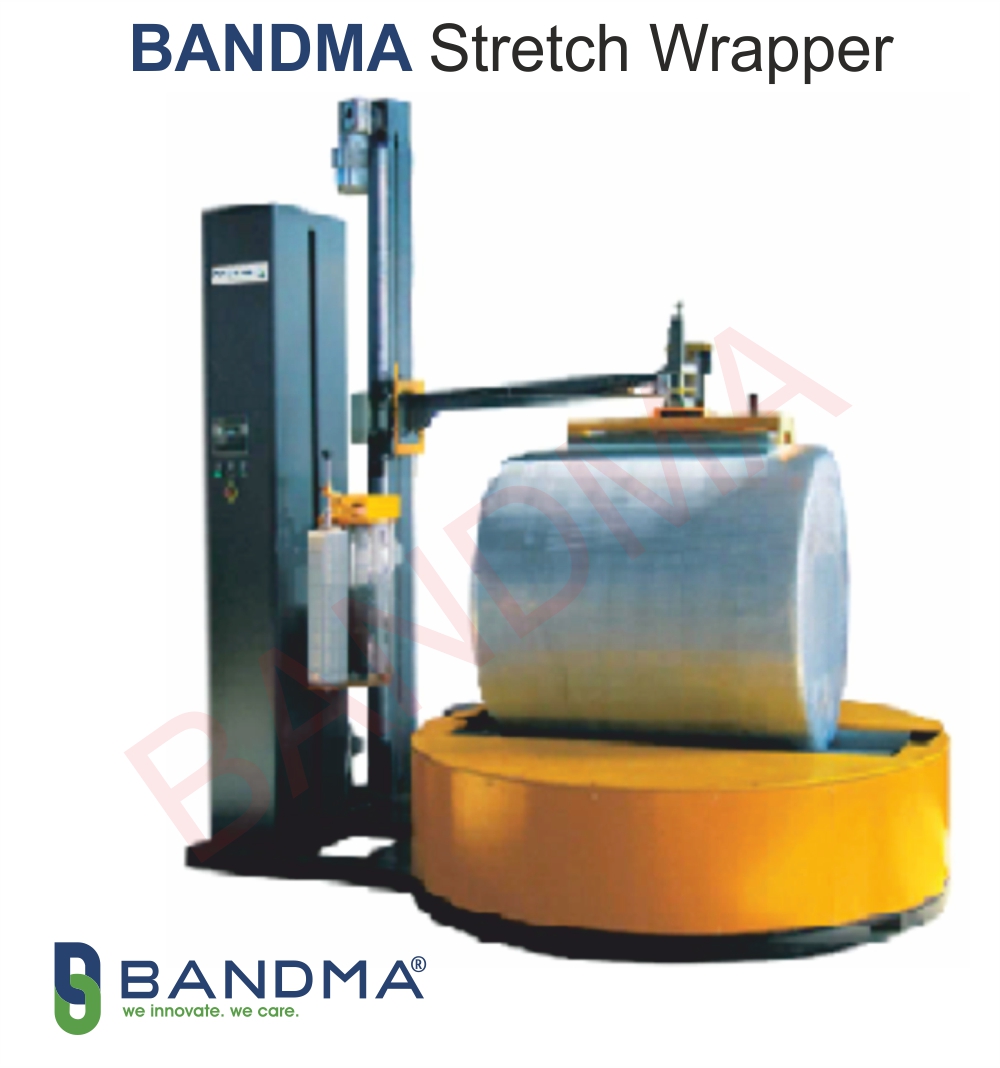

In the world of secondary packaging, stretch wrapping plays a crucial role in keeping palletized goods safe, stable, and ready for transport. Yet, many businesses unknowingly make avoidable mistakes that compromise load integrity, increase film usage, or even lead to product damage during shipping.

Whether you’re using a semi-automatic or fully automatic stretch wrapper—or still doing it manually—avoiding these common errors can save you time, money, and headaches.

Let’s break down the top five stretch wrapping mistakes and how to steer clear of them.

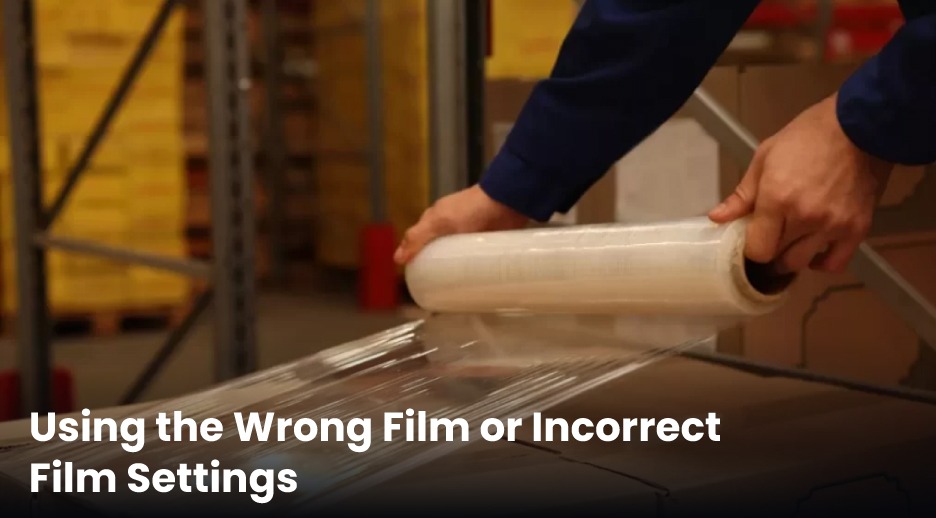

1. Using the Wrong Film or Incorrect Film Settings

Not all stretch films are created equal. Choosing the wrong type, too thin, too thick, or incompatible with your machine, can cause breakage, slippage, or excessive film use.

Common issues:

- Film snapping mid-cycle

- Poor load containment

- Wrapping too tight and crushing lightweight products

- Excess film usage due to poor stretch settings

How to avoid it:

- Match your film type (gauge, pre-stretch capability, cling level) with your machine and load requirements.

- If your machine supports pre-stretching, optimize the settings to reduce film use while maintaining tension.

- Work with suppliers who understand your application and can recommend the correct film/machine pairing.

2. Wrapping Too Loose or Too Tight

Incorrect tension is a silent killer in pallet stability. Loose wrapping causes loads to shift during transport. On the other hand, over-tightening can crush boxes or distort products, especially lightweight or fragile items.

How to avoid it:

- Set proper tension based on the load type and product weight.

- Test with a trial pallet to ensure the wrap provides secure containment without damage.

- Invest in machines with adjustable or programmable tension control to fine-tune wrapping based on SKU or shipment.

3. Inconsistent or Incomplete Wrapping Cycles

Operators sometimes skip wrapping the bottom or top layers properly, especially during manual or semi-automatic operation. This leads to pallets that look secure but fail in transit.

Signs you’re doing this:

- The bottom of the pallet is loosely wrapped or exposed.

- Load shifts on forklifts or during shipping.

- Film doesn’t anchor the product to the pallet base.

How to avoid it:

- Use machines with automatic bottom/top wrap settings to ensure consistency.

- Make sure the film overlaps the pallet base for a secure "lock-in".

- Train operators to never skip full cycles, even under time pressure.

4. Ignoring Machine Maintenance

Like any mechanical system, stretch wrappers need routine checks. Dirty rollers, misaligned sensors, or worn-out film carriage components can impact wrap quality and lead to downtime.

What can go wrong:

- Film breaks more often

- Tension becomes inconsistent

- The wrapper stops mid-cycle

- Energy consumption increases due to worn parts

How to avoid it:

- Schedule routine inspections, especially for pre-stretch rollers, film brakes, and motors.

- Keep film sensors clean and well-calibrated.

- Replace worn components before they fail.

- Partner with suppliers who offer preventive maintenance or AMC options.

5. Not Tailoring Wrap Settings to Different Load Types

One-size-fits-all doesn’t work in stretch wrapping. A bulky drum pallet and a stack of cartons don’t need the same number of rotations, film tension, or wrap height.

What happens when you don’t adjust:

- Fragile goods may get damaged

- Over-wrapping leads to film waste

- Under-wrapping results in unstable loads

- Machines wear faster due to excessive cycles

How to avoid it:

- Use programmable logic control (PLC) settings to create preset wrap patterns.

- Train your team to select the right wrap program for each product line.

- If you handle varied load types, invest in smart machines with multiple load profiles and memory functions.

Conclusion: Avoiding These Mistakes Saves More Than Just Film

Fixing these common stretch wrapping errors does more than improve packaging quality. It also leads to:

- Lower material costs (less wasted film)

- Reduced transport damage and returns

- Better pallet appearance for retail display

- Increased operational efficiency and less downtime

A well-set-up stretch wrapping system acts as the final guard before goods leave your facility. It's not just about wrapping, it’s about protection, presentation, and performance.

Bonus Tip: Partner with the Right Supplier

Many of these issues can be prevented right at the procurement stage, by choosing the right equipment and support. A reliable packaging machinery supplier will:

- Recommend machines suited to your volume and load types

- Help you set up proper film-tensioning and wrap programs

- Provide after-sales support and spare parts

- Guide your team through training and safety practices

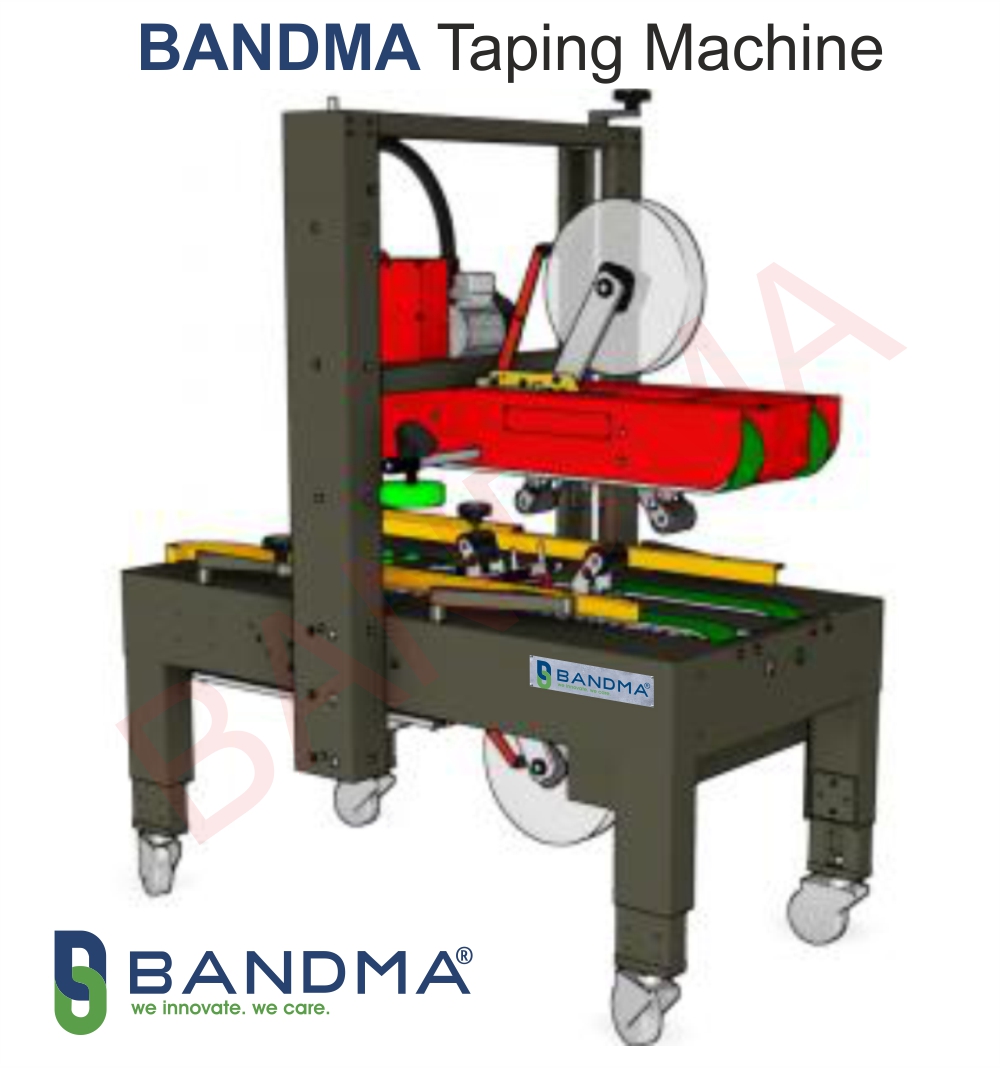

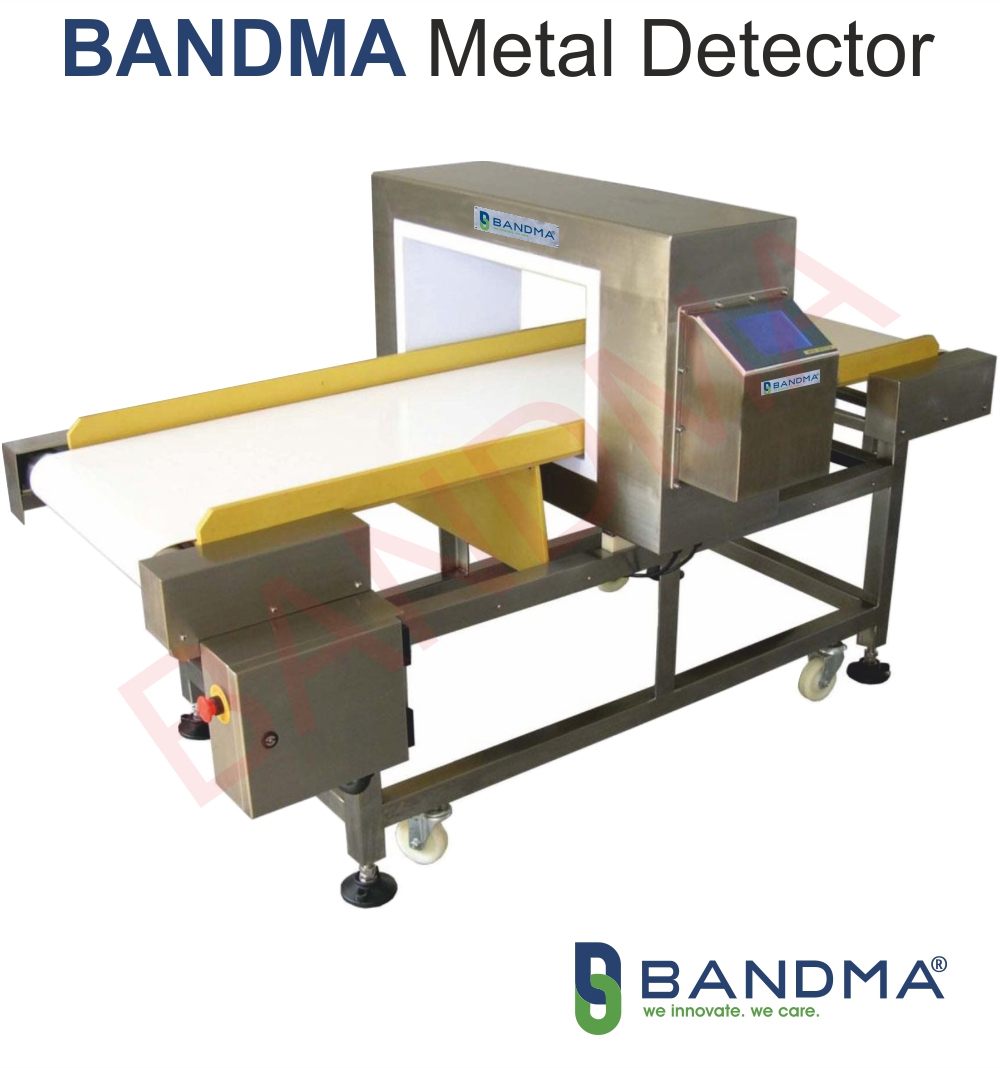

At Bandma, we specialize in delivering stretch wrapping solutions built for high performance, load security, and long-term value. Whether you need a semi-automatic model or a fully integrated system, we’re here to make your packaging process smoother and smarter.