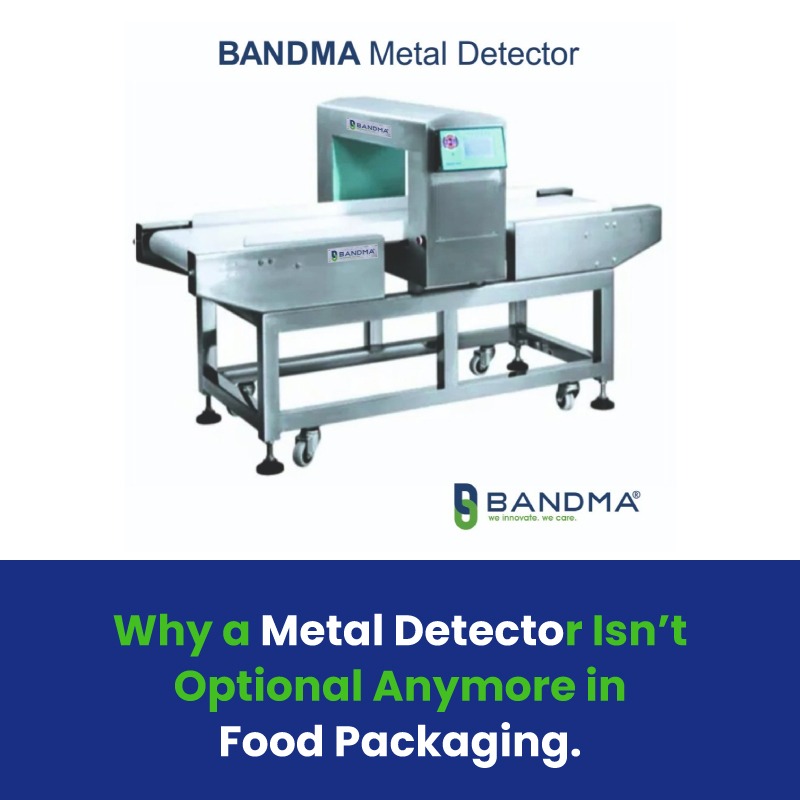

In today’s fast-moving food industry, safety isn't just a priority, it’s a promise your brand makes to every customer. With global regulations tightening and consumers becoming more conscious about what they consume, manufacturers can no longer afford to leave quality control to chance. One essential piece of equipment making a big difference is the industrial metal detector.

Whether you're packaging snacks, grains, spices, ready-to-eat meals, or even frozen foods, installing a reliable metal detection system is no longer a luxury, it’s a requirement for survival and growth.

The Rise in Contamination Awareness

Food recalls due to physical contamination have made headlines around the world. Often, these incidents involve metal fragments accidentally entering products during the manufacturing process. These could come from machinery wear, broken tools, or damaged processing lines. Even the smallest shard of metal can lead to serious consequences—from harm to consumers to legal action, financial penalties, and loss of reputation.

More than ever, manufacturers are expected to follow global safety norms such as:

- FSSAI guidelines in India

- HACCP and ISO 22000 certifications

- BRCGS standards for global export

- FDA and EU regulations for international compliance

Failing to detect contaminants early can result in product recalls, import bans, or cancelled orders from retail partners.

So, Why Is Metal Detection Essential Today?

1. Mandatory for Compliance

Regulatory bodies now expect food businesses to implement preventive controls—especially when exporting. Metal detectors help meet traceability and documentation standards. If you don’t have one, you’re at risk of failing audits or losing export certification.

2. Brand Protection and Consumer Trust

One contamination complaint on social media can damage years of brand-building. Consumers today expect transparency and safety. A metal detector reinforces trust by serving as the last line of defense before your product reaches the market.

3. Reduces Risk of Recalls

Recalls are not only expensive but also damaging to long-term customer relationships. A good quality metal detector can identify even micro-level contaminants, saving you from unwanted disruptions.

4. Supports Quality Control Goals

Metal detectors support total quality assurance by verifying that finished products meet safety requirements. Many systems can log reports and create digital records for inspection or auditing purposes.

5. A Competitive Advantage

As global buyers become stricter, having advanced inspection systems gives your product an edge in B2B and export markets. It shows you're committed to delivering the safest possible product.

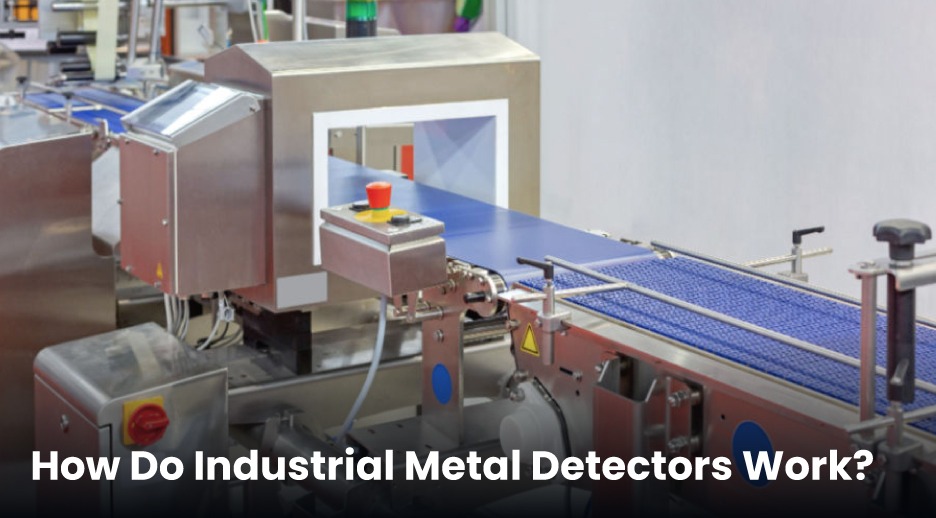

How Do Industrial Metal Detectors Work?

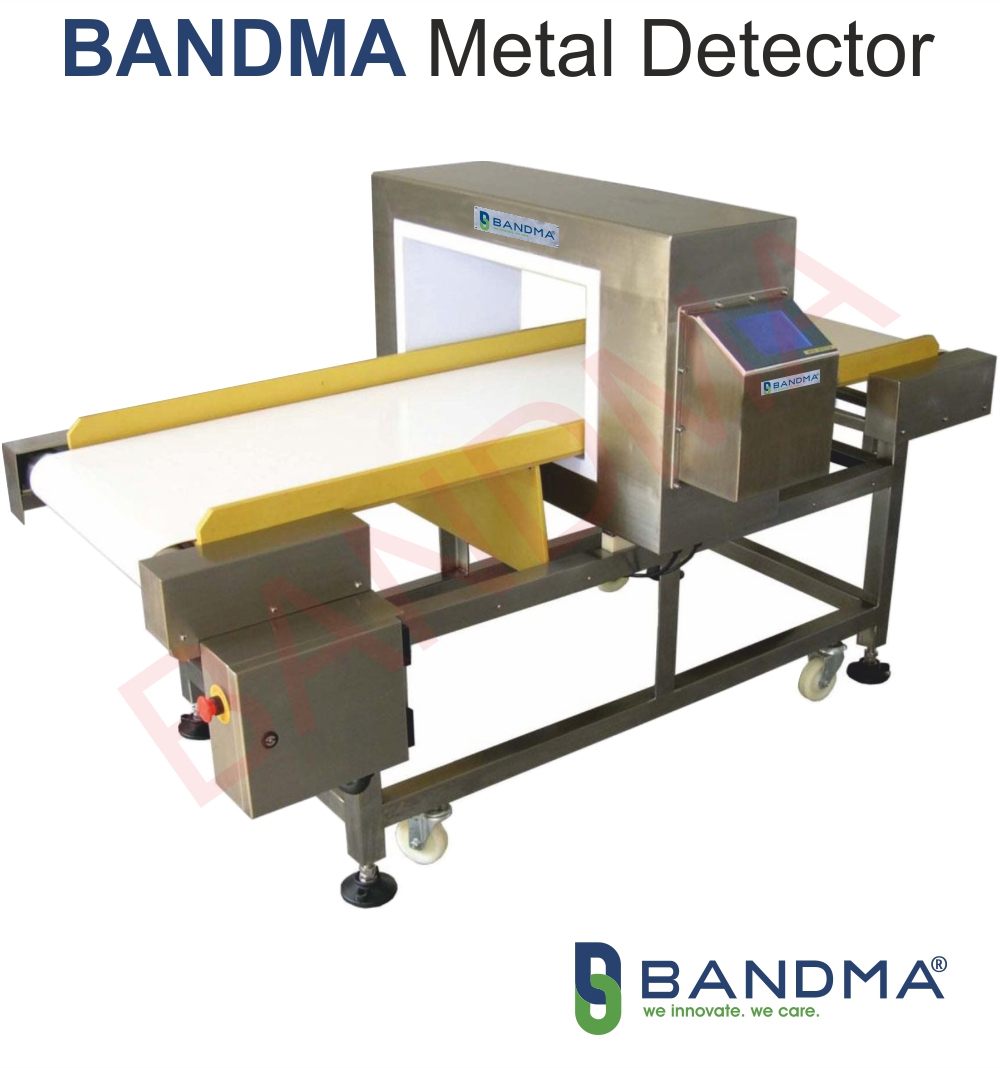

Industrial metal detectors used in packaging lines operate through electromagnetic fields. As the product passes through the detection head, the machine measures changes in the field caused by the presence of metal particles. When contamination is detected, the system triggers an automatic reject mechanism—such as an air blast or belt diverter—without disrupting the production flow.

Different technologies are used for different food types:

- Balanced coil systems are common for dry goods.

- Multifrequency systems are better suited for high-moisture products like meat or dairy, where product conductivity may interfere.

The goal is always the same: detect contamination before the product leaves your plant.

Real-World Example: Avoiding a Costly Recall

Consider a mid-sized snack manufacturer who was exporting seasoned chips to Europe. A routine audit flagged the absence of a proper metal detection system. As a result, the entire shipment was held at port, inspected manually, and delayed by over two weeks—causing serious financial loss and a strained distributor relationship.

After installing an in-line metal detector, not only did the company meet compliance requirements, but it also restored client confidence and reduced wastage by 18% in six months.

Quick FAQs About Metal Detection in Packaging

Q1: Can a metal detector work with foil-wrapped products?

Yes, but it requires a specialized technology such as X-ray inspection or ferrous-in-foil detection. Standard detectors may not be effective in these cases.

Q2: How often should I calibrate the machine?

Calibration is recommended at least once per shift or batch. Many advanced systems offer auto-calibration for accuracy.

Q3: Do I need separate machines for different product lines?

Not always. Some machines can store multiple product profiles and switch between them easily.

Q4: What contaminants can be detected?

Commonly detected materials include ferrous metals, stainless steel, and non-ferrous metals like aluminum, brass, and copper.

Maintenance and Operator Awareness Matter Too

Even the best metal detector won't be effective if it's poorly maintained or incorrectly operated. That’s why regular cleaning, calibration, and training are just as important as the machine itself.

Manufacturers should ensure:

- Routine maintenance schedules are followed

- Test cards are used to verify detection

- Staff is trained on proper reject handling and data recording

Well-maintained systems not only reduce risk but also extend the machine's working life.

Final Word: Investing in Metal Detection Is Investing in Trust

Choosing to install a metal detector in your packaging line is more than just a regulatory decision—it’s a long-term investment in your product’s credibility and your brand’s future.

In a competitive, safety-conscious market, every step you take toward quality assurance brings you closer to sustainable growth. The food industry isn’t just evolving—it’s raising the bar. The question is, will your packaging line rise with it?

Need help choosing the right solution?

At Bandma, we offer a complete range of industrial metal detectors tailored for food safety, compliance, and speed. Let us help you protect your brand—batch after batch.